E-beam stands out as the more energy-efficient and cost-effective choice compared to x-ray systems. Industries that depend on electron beam technologies face significant differences in Energy Conversion Efficiency and processing costs. The following table shows how electron beam irradiation equipment outperforms x-ray systems:

| Technology Type | Estimated Split (%) |

|---|---|

| E-Beam | 80 |

| X-Ray | 20 |

Companies benefit from electron equipment’s lower power consumption, reduced capital costs, and growing market adoption. Choosing electron beam irradiation equipment gives users practical advantages in sustainability and cost control.

Key Takeaways

- E-beam technology is more energy-efficient than x-ray systems, with up to 80% energy conversion efficiency compared to only 10-12% for x-rays.

- Choosing electron beam irradiation can significantly lower processing costs due to reduced power consumption and faster processing times.

- E-beam systems are eco-friendly, producing fewer emissions and no toxic byproducts, making them a sustainable choice for industries.

- Industries benefit from the versatility of e-beam technology, which is effective for sterilization, material processing, and environmental cleanup.

- When selecting sterilization technology, consider factors like speed, cost, and environmental impact to make the best choice for your needs.

Technology Basics

E-Beam Overview

Electron beam irradiation relies on accelerated electrons to interact with the molecular structure of materials. The process uses electron accelerators to propel electrons to near-light speeds. When the electron beam strikes a material, it transfers energy, causing chemical or physical changes.

- Accelerated electrons penetrate surfaces and trigger molecular changes.

- The technology achieves rapid processing, often completing tasks in seconds.

- Electron beam irradiation eliminates toxic byproducts, making it eco-friendly.

- Operators benefit from precise control, tailoring treatments to specific requirements.

- The versatility of electron beam irradiation extends to sterilization, polymer enhancement, and environmental cleanup.

Electron beam irradiation has proven effective in environmental pollution control. It degrades organic pollutants, removes heavy metal ions, and inactivates harmful microorganisms. Industries use electron beam systems for wastewater treatment, air purification, and solid waste degradation. Recent advancements show that high-temperature electron beam irradiation can reduce energy costs for recycling PTFE by 50%, making the process more commercially viable.

X-Ray Overview

X-ray irradiation uses advanced mechanisms to deliver targeted radiation. The core components include linear accelerators, multileaf collimators, and intensity modulated radiation therapy.

| Mechanism/Component | Description |

|---|---|

| Linear Accelerators (linacs) | Increase accuracy in targeting tumors. |

| Multileaf Collimators (MLCs) | Adjust the shape of the radiation field for precision. |

| Intensity Modulated Radiation Therapy | Target irregularly shaped tumors while sparing healthy tissue. |

| Image-Guided Radiotherapy | Ensure accurate patient positioning before treatment. |

| Adaptive Radiotherapy | Replan during treatment to adapt to changes in tumor size or position. |

| Artificial Intelligence | Optimize treatment plans and enhance operational efficiency. |

| High Dose Rate Irradiation (FLASH) | Deliver radiation at high rates to minimize damage to normal tissues. |

Recent improvements in x-ray and electron beam technologies have increased energy efficiencies in agriculture and food processing. These advancements support broader commercial adoption.

Key Differences

| Feature | Electron Beam (E-Beam) | X-Ray |

|---|---|---|

| Speed | High-speed sterilization, process in minutes | Slower, better for high-penetration needs |

| Sustainability | Operates on grid electricity, no harmful by-products | More power-intensive, cleaner than EO |

| Material Compatibility | Best for low-density items, simple geometries | Suitable for dense, complex items |

| Cost Efficiency | Most cost-effective for high-volume sterilization | Higher infrastructure and operational costs |

| Reliability & Track Record | Well-established, reliable, minimal maintenance | Newer, still establishing reliability |

E-beam systems excel in speed, sustainability, and cost efficiency. X-ray systems offer deeper penetration and advanced targeting, making them suitable for specialized applications.

Energy Conversion Efficiency

E-Beam Efficiency

Electron beam irradiation equipment demonstrates high energy conversion efficiency. The process uses linear accelerators to generate and direct high-energy electrons with precise control over beam intensity and direction. This direct application of electron energy to materials results in minimal energy loss and high uniformity in treatment outcomes. Industries benefit from reduced energy consumption and lower carbon footprints. Electron beam treatment supports sustainability goals and leads to long-term cost savings.

- Electron beam irradiation utilizes linear accelerators for generating high-energy electrons.

- The process allows for precise control, ensuring uniformity in energy delivery.

- Energy conversion efficiency remains superior compared to conventional methods.

- Lower energy consumption supports sustainability and cost reduction.

- Electron beam treatment achieves consistent uniformity across processed materials.

Conversion to X-Rays

The conversion to x-rays introduces significant energy loss. When high-energy electrons strike a target material, most of their energy transforms into heat rather than x-ray photons. The primary mechanism, bremsstrahlung radiation, occurs as electrons decelerate near atomic nuclei, producing high-energy x-rays. However, only a small fraction of the electron energy converts to x-ray irradiation, with the majority lost as heat.

- The x-ray conversion efficiency ranges between 8% and 9%.

- Approximately 91% to 92% of input energy is lost during conversion to x-rays.

- Collisional energy exchanges convert most electron energy into heat.

- Only a small fraction of electrons produce high-energy x-rays through bremsstrahlung radiation.

- About 99% of the kinetic energy of incoming electrons becomes heat, with the remainder forming x-ray irradiation.

- The law of conservation of energy governs this process, resulting in low overall efficiency.

X-Ray Irradiation Efficiency

X-ray irradiation operates with much lower energy conversion efficiency compared to e-beam equipment. The efficiency of x-ray irradiation typically falls between 10% and 12%, while electron beam systems can reach higher values under optimal conditions. This low efficiency hindered the practicality of volume x-ray sterilization until the development of commercial linear accelerators with power exceeding 100kW. The uniformity of x-ray irradiation depends on the system design and the distribution of high-energy x-rays, but energy losses remain a major challenge.

| Technology | Environmental Impact | Source |

|---|---|---|

| Electron Beam | Gaining importance for pollution mitigation, used in various thermal and radiation techniques. | Woods and Pikaev (1994), Bradley (1984), Bakish (1962) |

| X-Ray | High energy capable of breaking chemical bonds, contributing to ionization processes. | Bradley (1984), Bakish (1962) |

Industries must consider both energy conversion efficiency and environmental impact when choosing between electron beam treatment and x-ray irradiation. Electron beam systems offer greater uniformity, higher efficiency, and lower energy consumption. X-ray irradiation provides deep penetration with high-energy x-rays but suffers from substantial energy loss during conversion. The choice depends on the required uniformity, sustainability goals, and operational costs.

Processing Costs

E-Beam Costs

Electron-beam accelerator offer a cost-effective solution for many industries. The main components of processing costs for these systems include staffing, electrical power, maintenance, and supplies. Operators at electron beam industrial facilities often require only a small team. Typically, one to four handlers and a technician manage maintenance and calibration. Electrical power consumption depends on system size. Smaller electron-beam accelerator units may use about $4 per hour, while larger systems can reach $15 to $20 per hour. Maintenance costs focus on replacing electronic parts, with service life ranging from 10,000 to 25,000 hours. Supplies, such as radiochromic films for dosimetry, add about $3 per hour.

| Component | Description | Cost Range |

|---|---|---|

| Staffing | Requires 1 to 4 handlers and a technician for maintenance and calibration. | Varies based on system size |

| Electrical Power | Consumption varies with system size, smaller systems at ~$4/hr, larger at $15-$20/hr. | $4/hr to $20/hr |

| Maintenance | Replacement parts for electronic components, service life 10,000 to 25,000 hours. | Majority of maintenance cost |

| Supplies | Regular purchase of dosimetry supplies, e.g., radiochromic films at ~$3/hr. | $3/hr |

Labor expenses make up a large part of service costs. Skilled technicians play a key role in keeping electron-beam accelerator running smoothly. Parts variability can cause maintenance costs to fluctuate. The complexity of these systems means that strategic planning is important for controlling expenses. Unlike other radiation processing methods, e-beam systems do not need consumable chemicals. This reduces both procurement and disposal costs. Energy efficiency remains a strong advantage, as electron-beam systems use less power than x-ray systems for similar processing tasks. Rapid processing speeds also help lower per-unit costs, making e-beam a preferred choice for high-volume operations.

Tip: Regular maintenance and skilled staff help maximize the lifespan and efficiency of electron-beam accelerator.

X-Ray Costs

X-ray irradiation systems present a different cost structure. The shift from older radioactive isotope-based irradiators, such as those using Cesium-137, has increased demand for x-ray technology. Safety and security concerns drive this change. X-ray irradiators only emit radiation when activated, which reduces regulatory and liability costs. However, operational costs remain high due to system inefficiency. X-ray systems convert only a small portion of electron energy into usable x-rays. Most energy becomes heat, which leads to higher electricity bills and increased cooling requirements.

- X-ray systems require more power for the same processing output as electron-beam accelerator units.

- Maintenance costs can rise due to the need for specialized parts and frequent servicing.

- Staffing requirements may increase because inconsistent image quality and workflow inefficiencies often lead to retakes and wasted resources.

- These factors place a financial burden on facilities that rely on x-ray radiation processing.

X-ray systems do not use hazardous radioactive materials, which lowers some regulatory costs. However, the inefficiency of the process means that operational costs stay higher than those for electron-beam accelerator.

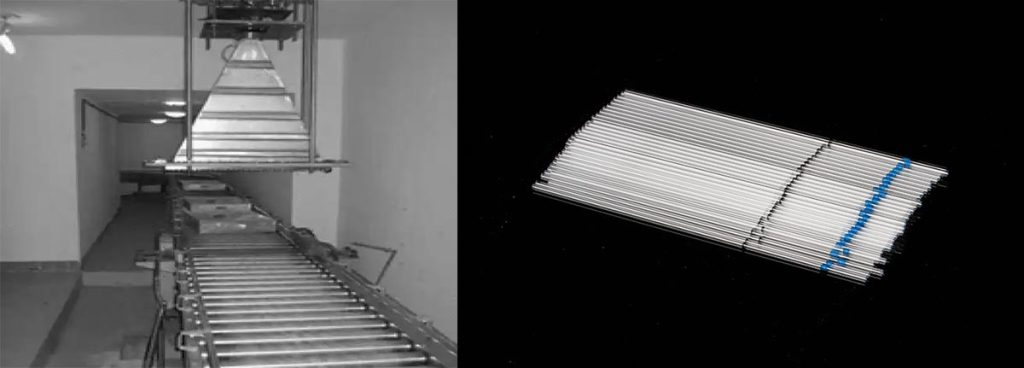

Scalability

Scalability plays a crucial role in selecting a radiation processing technology for large-scale operations. Electron-beam accelerator excels in this area. They can process many truckloads of products each day. The process delivers sterilization doses in minutes or even seconds. This speed supports high throughput and makes e-beam technology the most economical choice for many products, especially medical devices. The sustainability of electron-beam accelerator also stands out. These systems produce low emissions and run on commercial power.

| Feature | Electron Beam (E-Beam) | X-Ray Technology |

|---|---|---|

| Scalability | Can process many truckloads of products daily | Less scalable compared to E-Beam |

| Speed | Sterilization dose in minutes or seconds | Slower processing time |

| Sustainability | Low emissions, runs on commercial power | Higher emissions |

| Economics | Most economical for many products, especially medical devices | More expensive to deploy |

X-ray technology offers deep penetration, but it processes materials more slowly. Higher emissions and greater deployment costs limit its scalability. The electron-beam accelerator market continues to grow at a compound annual growth rate of 8.5%. The FDA recognizes e-beam as a safe and effective sterilization method. Many industries choose electron-beam accelerator systems for their ability to scale up radiation processing efficiently.

Note: Facilities that require rapid, large-scale processing often select electron-beam accelerator for its speed, sustainability, and cost advantages.

Applications

Sterilization

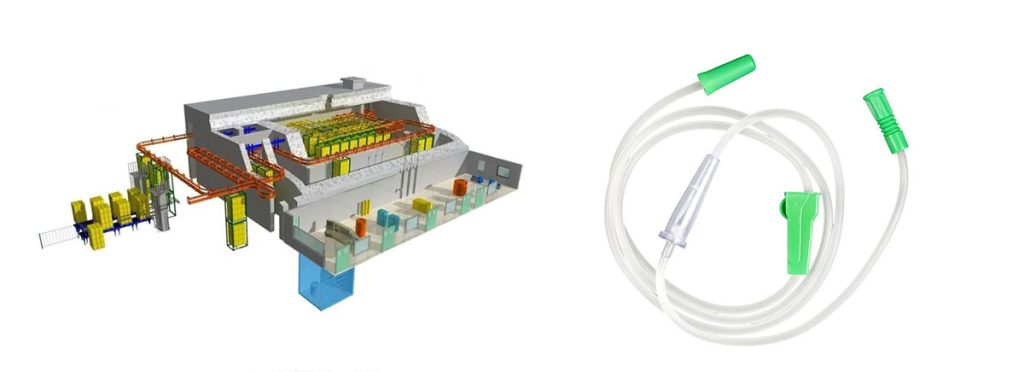

Sterilization remains a critical process in the medical industry. Hospitals and manufacturers rely on several methods to ensure the safety of medical devices and supplies. Gamma radiation leads the market, but electron beam and x-ray sterilization technologies have gained traction for specific needs. These methods offer effective sterilization for heat-sensitive and single-use medical products. The adoption of electron beam and x-ray sterilization reflects a shift toward eco-friendly and cost-effective solutions.

| Technology | Common Applications |

|---|---|

| Electron Beam | Single-use devices, heat-sensitive devices, stents, blood products, plastic tubing, surgical components |

| X-Ray | Medical equipment, including gowns and gloves |

| Gamma Radiation | Medical device and biopharmaceutical product sterilization |

Medical device manufacturers often choose electron beam sterilization for polymer-based products. X-ray sterilization is preferred for items that require deep penetration, such as medical gowns and gloves. The medical field values these technologies for their ability to reduce bioburden and ensure patient safety.

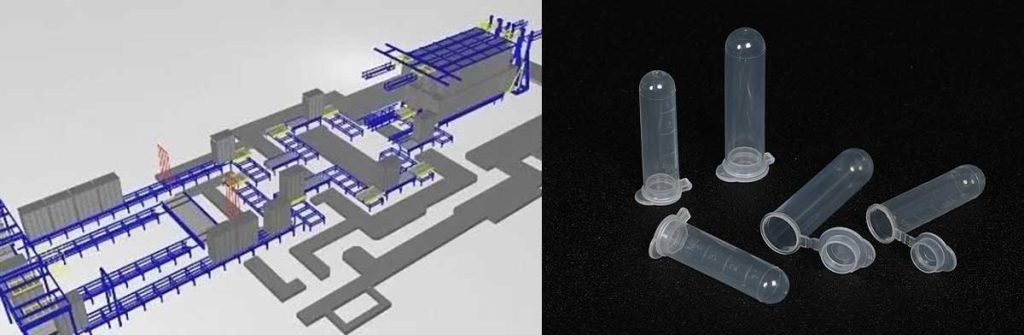

Industrial Use Cases

Industries outside the medical sector also benefit from radiation sterilization. Food irradiation uses electron beam and x-ray systems to eliminate microorganisms and extend shelf life. Material processing relies on e-beam to improve the properties of polymers through crosslinking. Other notable applications include gemstone color enhancement, semiconductor doping, and postal mail decontamination.

- Food irradiation enhances safety and shelf life.

- Medical device sterilization reduces contamination risks.

- Material processing improves product durability and performance.

- Gemstone color enhancement and semiconductor doping support specialized manufacturing.

- Postal mail decontamination ensures safe delivery.

These diverse applications highlight the versatility of radiation sterilization technologies.

Choosing Electron Beam Irradiation Equipment

Selecting the right sterilization technology depends on several factors. Medical device manufacturers consider technical specifications, economic impact, processing time, and environmental sustainability. Electron beam irradiation equipment offers fast processing, tight dose uniformity, and reliable performance for many medical products. However, large or dense items may require x-ray sterilization due to its deeper penetration.

| Criteria | Electron Beam Systems | X-Ray Systems |

|---|---|---|

| Technical Specifications | Balanced energy requirements, effective shielding | Varies by design |

| Economic Considerations | Lower operational costs | Higher transportation and operational costs |

| Processing Time | Seconds | Hours to days |

| Sustainability & Environmental Impact | Dependent on electricity source | Dependent on electricity source |

Regulatory standards and market trends also influence the choice between electron beam and x-ray sterilization. The global market for electron beam irradiation equipment continues to grow, driven by demand for efficient and sustainable sterilization in the medical and food industries.

Conclusion

Recent studies highlight that electron beam technology delivers high beam power and short processing times, while x-ray systems offer deeper penetration but suffer from low conversion efficiency and significant heat loss.

| Technology Type | Advantages | Limitations |

|---|---|---|

| Electron Beam | High beam power, fast processing | Limited penetration depth |

| X-Ray | Deep penetration | Low efficiency, high heat loss |

These differences should guide companies to match their needs with the right technology. Decision-makers benefit from evaluating both technical performance and long-term costs before investing in irradiation equipment.

FAQ

What Is the Main Difference Between E-Beam and X-Ray Irradiation?

E-beam uses accelerated electrons to treat materials directly. X-ray irradiation relies on converting electron energy into x-rays, which penetrate deeper but lose more energy as heat.

Why Do Industries Prefer E-Beam for High-Volume Processing?

Industries choose e-beam for its fast processing speed and lower operational costs. The technology supports high throughput and reduces energy consumption, making it ideal for large-scale sterilization.

How Does X-Ray Technology Benefit Medical Device Sterilization?

X-ray systems provide deep penetration, which helps sterilize dense or complex medical devices. This technology ensures thorough treatment for items that e-beam cannot process effectively.

What Are the Environmental Impacts of E-Beam and X-Ray Systems?

E-beam systems produce fewer emissions and use less power. X-ray systems require more energy and generate more heat, which increases cooling needs and environmental impact.

Can Facilities Switch from X-Ray to E-Beam Easily?

Facilities may need to upgrade equipment and retrain staff. E-beam systems offer simpler operation and maintenance, but switching requires careful planning to meet regulatory standards.