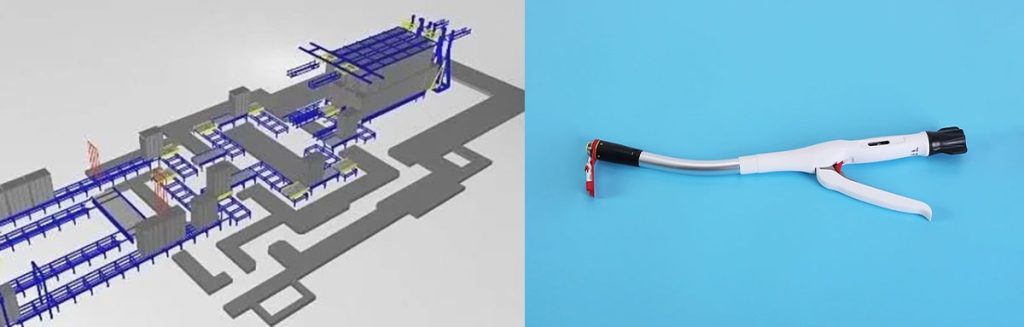

Manufacturers now see rapid gains in efficiency by integrating e-beam equipment into their production lines. Recent industry data shows:

- Over 60% adoption rate in U.S. medical sterilization units

- Strong demand from automotive, aerospace, and electronics manufacturers drives growth in industrial applications

- E-beam technology improves precision and sustainability in manufacturing processes

| Industry | Productivity Gains | Description |

|---|---|---|

| Healthcare | Improved durability and performance | Electron beam surface modification enhances longevity of critical healthcare tools. |

| Aerospace | Unmatched precision in welding | Electron beam welding creates robust connections for aircraft and spacecraft components. |

Careful planning and collaboration help teams achieve seamless integration with minimal disruption, setting the stage for continuous improvement.

Key Takeaways

- Integrating e-beam equipment boosts production efficiency and product quality, making it a valuable addition to manufacturing lines.

- Conduct a thorough review of your current production line to identify bottlenecks and ensure a smooth integration process.

- Set clear objectives for the integration to align with business goals, such as improving safety and optimizing sterilization.

- Regularly update standard operating procedures (SOPs) to reflect new safety measures and operational steps after integration.

- Monitor performance with key indicators to ensure consistent quality and support continuous improvement in production.

Assessment

Current Line Review

A thorough review of the current production line forms the foundation for successful integration of e-beam equipment. Teams should examine key operational parameters to understand the baseline and identify potential bottlenecks. The following table highlights essential factors to evaluate:

| Parameter | Description |

|---|---|

| Current (mA) | Measures the number of electrons produced over time, affecting the dose received by the product. |

| Line Speed | The speed at which the product passes through the electron beam, influencing the dose delivered. |

| Power Capability | Measured in kW, higher power allows for greater product throughput. |

In addition, teams must assess temperature control, vibration management, and cleanroom standards. Temperature control ensures electron beam stability and accurate measurements. Vibration management is crucial because even minor vibrations can disrupt the process. Cleanroom standards, such as ISO Class 5 or higher, help prevent particle contamination.

Integration Points

Identifying optimal integration points within the production line maximizes the benefits of electron beam irradiation equipment. Teams should map out where the new system will interact with existing processes. This step often reveals challenges that require attention:

- Resolution limits and throughput issues may arise.

- Proximity effects and electron scattering can affect pattern accuracy.

- The slow serial writing process sometimes limits scalability.

- Material compatibility impacts quality and reliability.

- High equipment and operational costs may restrict accessibility.

Tip: Early identification of these challenges allows for proactive solutions, reducing the risk of delays during installation.

Compatibility Check

Compatibility checks ensure that e-beam equipment will function smoothly with current systems. Teams should verify that all materials and components can withstand electron beam exposure. They must also confirm that software and hardware interfaces align with existing automation protocols. This step prevents unexpected downtime and maintains product quality throughout the integration process.

Goals & Requirements

Objectives

Companies set clear objectives before installing e-beam equipment in their production lines. These goals help guide the process and measure success. Teams often focus on improving inspection, advancing technology, and adopting new production techniques. Many organizations also aim to optimize sterilization, enhance safety, and promote sustainability. The following list highlights common objectives:

- Enable finer levels of inspection for quality control.

- Support advancements in e-beam technologies.

- Facilitate a shift toward advanced production techniques.

- Optimize sterilization processes for medical devices.

- Enhance patient safety and promote sustainability.

- Increase cost-effectiveness in manufacturing.

- Address challenges of increasing complexity in production.

- Manage shrinking geometries in products.

- Enhance operational efficiency and improve product quality.

Setting clear objectives ensures that every step of the integration process aligns with business priorities and delivers measurable results.

Compliance

Regulatory compliance plays a critical role when installing e-beam equipment. Each region has specific requirements that companies must meet. The table below outlines key compliance standards in major jurisdictions:

| Jurisdiction | Compliance Requirement |

|---|---|

| US and Canada | Registration with local authorities and establishment of an EB safety program. |

| European Union | License needed to import, install, and operate a self-shielded electron beam system. Must meet CE requirements. |

Manufacturers often face hurdles such as varying approval processes and stringent regulations. They overcome these challenges by following guidelines from regulatory bodies and educating consumers about the safety and benefits of e-beam technology.

Business Fit

E-beam equipment must align with business priorities such as cost reduction and product quality improvement. Companies evaluate how the new system supports their goals for efficiency and reliability. The following table summarizes the main benefits:

| Benefit Type | Description |

|---|---|

| Cost-Efficiency | EB irradiation provides a cost-effective alternative to traditional methods. |

| Quality Assurance | Ensures enhanced product quality, such as increased durability and safety. |

| Impact Area | Description |

|---|---|

| Increased Throughput | AI systems enhance precision and reduce manual intervention. |

| Cost Reduction | Facilities can lower operational costs while maintaining compliance. |

Case studies show that e-beam equipment delivers strong business benefits across industries. Medical and pharmaceutical companies maintain sterility without damaging products. Automotive and aerospace manufacturers improve reliability and performance. Polymer, plastics, and cable producers see gains in durability and strength.

Preparation

Site Setup

Successful integration of e-beam equipment begins with careful site setup. Teams assess the workspace to ensure safety and efficiency. They consult with facility experts to define project requirements and address challenges. Operators identify the material type, desired modifications, and required dose before accessing the electron beam irradiation facility. The following table highlights critical site setup considerations:

| Consideration | Description |

|---|---|

| Safety Protocols | Shielding systems prevent radiation leakage and protect operators. Monitoring systems ensure compliance with safety standards. |

| Budgeting | Evaluating costs for materials, transportation, and facility services is essential for planning. |

| Expert Consultation | Consulting with facility experts helps in assessing project requirements and ensuring compliance with safety protocols. |

Tip: Dedicated workshops with stable foundations and good ventilation support equipment safety. X-ray shielding rooms prevent radiation leakage.

Utilities & Safety

Manufacturing facilities must meet strict utility and safety requirements for e-beam equipment. Shielding and distance minimize radiation exposure to personnel. Regular maintenance checks prevent malfunctions and ensure equipment safety. Operators receive mandatory training on safe handling and emergency procedures. Oversight by the Nuclear Regulatory Commission and guidelines from OSHA and AAMI help maintain compliance. The table below summarizes key requirements:

| Requirement Type | Description |

|---|---|

| Radiation Protection | Ensuring minimal exposure to personnel through shielding and distance. |

| Equipment Safety | Regular maintenance checks on electron beam equipment to prevent malfunctions. |

| Training Programs | Mandatory training for operators on safe handling and emergency procedures. |

| NRC Regulations | Oversight by the Nuclear Regulatory Commission on radioactive materials. |

| OSHA Standards | Guidelines from the Occupational Safety and Health Administration. |

| AAMI Guidelines | Standards for medical device sterilization by the Association for the Advancement of Medical Instrumentation. |

Operators install e-beam equipment in rooms with proper ventilation and exhaust systems. Reliable grounding and insulation protect high-voltage components. Machines over 60 kV require lead shielding, and operators wear protective gear.

Workflow Changes

Integrating e-beam equipment transforms manufacturing workflows. Teams experience greater flexibility for rapid design changes. E-beam lithography systems allow new designs to be implemented in hours or days. This agility reduces downtime and boosts production efficiency. Quick pivots and iterations give companies a competitive advantage, especially in industries where speed to market matters.

- E-beam systems support rapid design changes.

- Reduced downtime enhances production metrics.

- Teams implement new designs quickly, improving agility.

Note: Workflow changes often lead to improved efficiency and faster response to market demands.

Training & Optimization

Staff Training

Effective staff training ensures safe and efficient operation of e-beam equipment. Companies often select programs that combine theory with hands-on experience. The PDA Electron Beam Sterilization course provides a comprehensive overview of electron beam systems, including regulatory and safety considerations. Participants learn about material effects and validation processes through interactive demonstrations and case studies.

| Training Program | Duration | Description |

|---|---|---|

| Basic Maintenance Training | Four days | Covers maintenance and technology of e-beam equipment. |

| Operator Training | One day | Conducted during machine start-up. |

| Dosimetry Short Course | N/A | Explains benefits and procedures for accurate analysis. |

| Customized Training Programs | N/A | Tailored for Marketing, Sales, and Customer Safety stakeholders. |

Training workshops often include tours that demonstrate electron beam theory and material effects. Validation exercises help staff understand system performance. Companies face challenges such as lack of engagement, multigenerational workforce issues, and dispersed teams. The table below highlights common obstacles:

| Challenge Type | Description |

|---|---|

| Lack of Engagement | Employees may not value training. |

| Multigenerational Workforce Issues | Comfort levels with new technologies vary. |

| Dispersed Workforce | Teams in different locations are harder to engage. |

| Lack of Time | Staff struggle to fit training into busy schedules. |

| Inability to Track Effectiveness | Measuring training success can be difficult. |

Tip: Interactive sessions and tailored programs increase engagement and improve learning outcomes.

SOP Updates

Standard operating procedures (SOPs) require regular updates after integrating e-beam equipment. Teams revise documentation to reflect new safety protocols, maintenance schedules, and operational steps. Clear SOPs help staff follow best practices and maintain compliance. Companies often include step-by-step guides for machine setup, dose measurement, and emergency procedures. Visual aids and checklists support consistent execution.

- Update SOPs to include e-beam safety measures.

- Add maintenance routines and troubleshooting steps.

- Provide clear instructions for dose verification.

Note: Well-documented SOPs reduce errors and support regulatory compliance.

Monitoring

Monitoring systems play a vital role in maintaining e-beam equipment performance. The beam monitoring system (BMS) uses ionization chambers to track beam position and flux in real time. Safety interlocks ensure that doses remain within set limits. Redundant design features minimize operational risks.

Key performance indicators (KPIs) help companies evaluate effectiveness after integration:

| KPI Name | Description |

|---|---|

| Production Efficiency (Pϵ) | Tracks downtime, output, and delivery plan adherence. |

| Level of Technological Obsolescence (Lto) | Assesses machine features, maintenance, and staff skills. |

| Compliance (C) | Measures adherence to regulatory procedures. |

| Production Quality Level (PQ) | Considers customer feedback and impact on sourcing and processes. |

Regular monitoring and KPI tracking allow teams to identify issues early and optimize production. Companies use these insights to improve efficiency and maintain high standards.

Regular monitoring ensures consistent quality and supports continuous improvement.

Conclusion

Integrating e-beam equipment transforms production lines through careful planning and collaboration. Companies report faster project turnarounds, higher throughput, and improved product quality. Teams benefit from reduced rework and material wastage, supporting sustainability goals.

| Benefit | Description |

|---|---|

| Higher Throughput | Increased production rates with e-beam technology. |

| Improved Product Quality | Enhanced material modification for better products. |

| Sustainability | Less material wastage aligns with green initiatives. |

Industry leaders recommend investing in automation, deploying advanced inspection technologies, and building strategic alliances. Continuous improvement relies on real-time monitoring and process optimization.

FAQ

What Are the Main Benefits of E-Beam Equipment for Production Lines?

E-beam equipment increases production speed and improves product quality. Teams see fewer errors and less waste. Automation helps operators manage tasks more efficiently. Companies report higher throughput and better consistency in results.

How Does Automation Impact E-Beam Integration in Production?

Automation streamlines production by reducing manual intervention. Operators use automated systems to monitor e-beam performance. This approach lowers downtime and boosts output. Automation also supports real-time adjustments, which keeps production running smoothly.

What Safety Measures Should Teams Follow During E-Beam Production?

Operators must follow strict safety protocols. Shielding systems protect workers from radiation. Automation monitors equipment status and alerts staff to risks. Regular training ensures everyone understands emergency procedures. Safety checks keep production safe and reliable.

Can E-Beam Equipment Work with Existing Automation Systems in Production?

Most e-beam equipment connects easily with current automation platforms. Integration allows teams to control production processes from a central system. Automation helps track performance and maintain quality. Compatibility checks ensure smooth operation.

How Does E-Beam Technology Support Sustainable Production Practices?

E-beam technology reduces material waste and energy use. Automation optimizes production schedules and resource allocation. Companies achieve sustainability goals by improving efficiency. E-beam systems help lower the environmental impact of production.