The main technical difference between pulsed and continuous electron beams lies in how they deliver energy—pulsed beams emit energy in bursts, while continuous beams provide a steady stream. Selecting the right type of electron beam plays a crucial role in technical applications. For example, electron beam sterilization offers rapid processing, avoids harmful chemicals, and maintains product integrity through precise dosing.

- This method increases efficiency in inventory management.

- It improves safety by eliminating carcinogenic gases and radioactive materials.

- Sterilization in original packaging reduces contamination risks.

A careful Technical Comparison helps engineers and scientists optimize performance and safety in demanding environments.

Key Takeaways

- Pulsed electron beams deliver energy in bursts, allowing for precise control and minimal heat impact, making them ideal for applications like sterilization and precision welding.

- Continuous electron beams provide a steady energy stream, ensuring consistent results in processes that require uniform heating, such as welding and sterilization.

- Choosing between pulsed and continuous beams depends on application needs, material properties, and desired thermal impact; engineers should evaluate these factors carefully.

- Pulsed beams excel in high-precision tasks, while continuous beams are better for high-speed operations; understanding these differences can enhance performance and efficiency.

- Regular maintenance and safety protocols are crucial for reliable operation of electron beam systems, ensuring both efficiency and operator safety.

Technical Comparison

Pulsed Electron Beams

Pulsed electron beams deliver energy in short, controlled bursts. Each pulse contains a high concentration of electrons, resulting in high peak power. This technical comparison shows that pulsed beams can achieve higher peak power density than continuous beams. The average power remains lower because the energy is not delivered constantly. Engineers often select pulsed beams for applications that require precise energy delivery and minimal thermal impact.

The temporal profile of a pulsed beam plays a critical role in technical performance. By analyzing the beam current distribution over time, scientists can develop accurate heat source models. These models help improve material surface quality during electron beam irradiation. The spatial-temporal characteristics of the beam also allow for better optimization of discharge structures, which enhances the performance of THz millimeter radiation sources.

Pulsed beams offer higher efficiency and deeper penetration when longer pulse durations are used. This makes them suitable for tasks that demand focused energy and minimal heat-affected zones. The ability to control the timing and duration of each pulse gives operators flexibility in scientific and industrial settings.

Continuous Electron Beams

Continuous electron beams provide a steady stream of electrons without interruption. In this technical comparison, continuous beams deliver average power consistently over time. The peak power remains lower than that of pulsed beams, but the total energy delivered can be higher due to the uninterrupted operation.

Continuous beams excel in applications that require uniform energy delivery. For example, in electron beam welding, a continuous beam ensures stable heat input and consistent weld quality. The lower penetration depth compared to pulsed beams makes continuous beams ideal for processes where surface modification is more important than deep penetration.

The continuous wave operation simplifies control and monitoring. Operators can maintain stable process conditions, which improves repeatability and reliability in manufacturing environments.

| Parameter | Continuous Wave (CW) | Pulsed Wave (PW) |

|---|---|---|

| Peak Power | Average pulse peak power | Higher peak power density |

| Average Power | Total power | Average pulse power |

| Energy Delivery | Lower penetration depth | Higher efficiency and penetration depth with longer pulse durations |

Pulsed Lasers vs. Continuous Lasers

The technical comparison between pulsed lasers and continuous lasers mirrors the differences seen in electron beams. Pulsed lasers emit energy in bursts, producing high-intensity peaks during each pulse. This high peak power enables precise material processing with minimal heat-affected zones. Pulse lasers are often used for micromachining, medical procedures, and scientific research where accuracy is critical.

Continuous lasers, on the other hand, provide a uniform intensity and continuous power output. This makes them suitable for applications that require sustained energy delivery, such as cutting, welding, and large-scale manufacturing. Continuous wave lasers create larger heat-affected zones, which can be beneficial or detrimental depending on the application.

| Aspect | Continuous Wave (CW) Laser | Pulsed Laser |

|---|---|---|

| Power Delivery | Continuous power output | Intermittent bursts with adjustable frequencies and durations |

| Beam Intensity and Focus | Uniform intensity | High-intensity peaks during pulses |

| Heat Management | Larger heat-affected zones | Minimal heat-affected zones |

| Efficiency | Energy-efficient for sustained applications | Efficient for precision tasks |

This technical comparison highlights how both pulsed and continuous lasers, like their electron beam counterparts, serve distinct roles in industry and research. Engineers choose between pulse lasers and continuous lasers based on the required balance of precision, efficiency, and thermal effects.

Applications

Electron Beam Sterilization

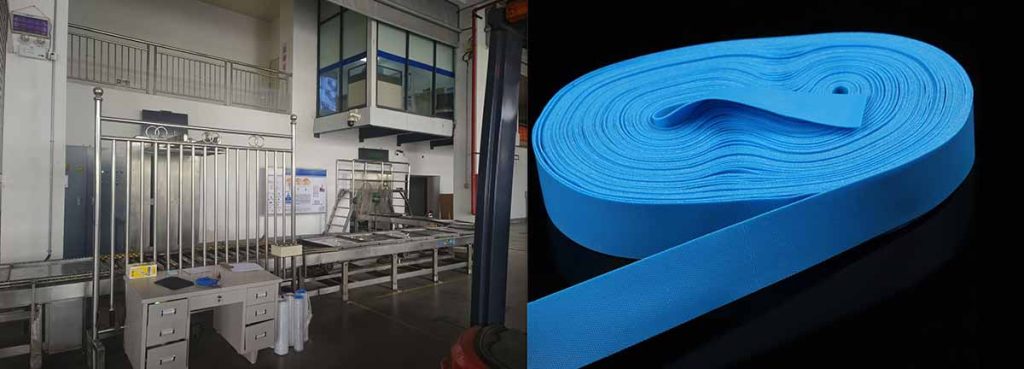

Electron beam irradiation equipment plays a vital role in sterilization processes. Engineers use pulsed electron beams to deliver precise doses of energy, which helps maintain product integrity. This method avoids the use of chemicals and reduces contamination risks. Pulsed beams allow for rapid processing, making them suitable for high-throughput environments. The ability to control pulse duration and intensity ensures effective sterilization without overheating sensitive materials. Continuous beams can also be used, but pulsed beams often provide better control over energy delivery, which is essential for delicate products.

The results described above provide the first compelling evidence that pulsed-beam TEM can indeed be used to mitigate specimen damage. However, much more work needs to be done, and the results still need to be replicated in other labs; other studies had different objectives and thus did not directly compare pulsed and conventional beams and did not apply the same level or type of experimental constraints.

Welding and Weld Quality

Welding applications benefit from both pulsed and continuous electron beams. Pulsed beams minimize heat input, which reduces part deformation. This feature is ideal for thin materials and precision welding. Continuous beams deliver steady energy, allowing for faster welding speeds and deeper penetration. However, this can generate more heat and cause distortion in sensitive materials. Engineers often select continuous beams for electron beam welding when they need consistent weld quality and process efficiency.

- Pulsed electron beams minimize heat input, reducing part deformation, which is ideal for thin materials and precision applications.

- Continuous electron beams provide steady energy output, allowing for faster welding speeds and deeper penetration, but can generate more heat and cause distortion in sensitive materials.

- Pulsed laser welding uses short bursts of energy, suitable for thin materials.

- Continuous wave (CW) laser welding emits a steady beam, beneficial for deep penetration in thicker metals.

Laser welding shares similar principles. Pulsed lasers excel in precision tasks, while continuous lasers support high-speed, deep-penetration welding. The choice between pulsed and continuous beams depends on material thickness, desired weld quality, and production speed.

Transmission Electron Microscopy

Transmission electron microscopy (TEM) relies on both pulsed and continuous electron beams for imaging. Pulsed beams enable ultrafast imaging techniques by providing temporal resolution beyond the readout rate of detectors. Scientists use stroboscopic illumination to form images from ultrashort electron pulses, achieving high temporal resolution. Dynamic TEM can resolve irreversible processes with temporal resolution down to tens of nanoseconds.

- Pulsed electron beams enable temporal resolution beyond the readout rate of detectors, allowing for ultrafast imaging techniques.

- Ultrafast transmission electron microscopy uses stroboscopic illumination to form images from ultrashort electron pulses, achieving high temporal resolution.

- Dynamic transmission electron microscopy can resolve irreversible processes with temporal resolution down to tens of nanoseconds.

Ultrafast electron microscopy requires pulsed beams with lower intensity compared to continuous beams. This leads to longer exposure times to match conventional TEM contrast. Technological advancements, such as direct electron detectors, have improved data acquisition, but balancing image quality and experimentation time remains a challenge. Continuous beams remain useful for routine imaging, while pulsed beams open new possibilities for studying fast processes.

Performance Factors

Power and Energy

Power and energy delivery play a central role in the performance of both pulsed and continuous electron beams. Pulsed beams deliver energy in short bursts, which results in high peak power. This high power output allows for greater penetration into materials, making pulsed beams suitable for applications that require deep penetration and minimal thermal impact. Continuous beams, in contrast, provide a steady power output over time. This steady delivery supports uniform energy transfer but usually results in lower peak power and less penetration compared to pulsed beams. Lasers show similar trends, with pulsed lasers offering high peak power for precision tasks and continuous lasers providing stable power for sustained operations.

- The choice between pulsed and continuous electron beams affects several performance metrics:

- Excitation efficiency

- Correlation function g(2)(0)

- Number of electrons per pulse

- Shape of the electron pulse

- Penetration depth and energy transfer

The number of electrons per pulse and the pulse shape directly influence the power output and penetration achieved. For pulsed beams, g(2)(0) is inversely related to the number of electrons per pulse, which depends on beam current and repetition rate. Both pulsed and continuous beams show similar dependence on the average number of bulk plasmons interacting with the sample.

Stability and Control

Stability and control are essential for reliable operation in laboratory and industrial environments. Pulsed electron beams, especially those using low-energy pulsed electron beam technology, demonstrate high efficiency and stability. This stability is crucial for processes like sterilization, where precise control over power and penetration ensures product quality. Pulsed beams allow operators to adjust pulse duration and intensity, providing better control over energy delivery. Continuous beams offer consistent power output, which simplifies process monitoring and control. However, higher throughput from continuous beams may sometimes compromise product integrity if not managed carefully. Lasers also reflect these characteristics, with pulsed lasers excelling in controlled, high-precision tasks and continuous lasers supporting stable, long-duration processes.

Efficiency

Efficiency measures how effectively a system converts input energy into useful work. Pulsed electron beams often achieve higher efficiency in applications that require focused energy and deep penetration. The ability to deliver high peak power in short bursts reduces energy waste and limits unwanted heating. Continuous beams, while efficient for processes that need steady power output, may lose efficiency when deep penetration or minimal thermal impact is required. Lasers follow a similar pattern. Pulsed lasers maximize efficiency in precision applications, while continuous lasers maintain efficiency in tasks that benefit from sustained power. Operators must consider the specific requirements of each application to select the most efficient beam type.

Operational Considerations

Maintenance

Proper maintenance ensures reliable operation of electron beam systems in industrial environments. Operators often encounter two main failure modes:

- Vacuum system failures can disrupt the focused electron beam, leading to poor weld quality and inconsistent deep penetration welds.

- Beam instability or misalignment often results from power supply fluctuations or contamination. These issues cause uneven welds and defects during the weld process.

Routine inspection and calibration help prevent these problems. Technicians monitor vacuum integrity and alignment to maintain optimal welding performance. Regular cleaning of beam paths and power supply checks also reduce downtime.

Tip: Scheduled maintenance reduces unexpected failures and extends equipment lifespan, especially in high-throughput welding applications.

Safety

Electron beams generate ionizing radiation, classified as beta radiation. This radiation can ionize molecules, posing health risks to operators. When electron beams interact with metals, they produce secondary x-rays. These x-rays travel longer distances and increase the risk of exposure. Facilities using electron beam welding must implement shielding and containment systems to protect workers. Low-energy electron beams require focused safety measures to contain hazards effectively. Training and strict protocols further enhance workplace safety.

Cost

The initial investment for electron beam systems ranges from several hundred-thousand to several million dollars. This substantial capital cost influences decisions in production environments, especially for welding operations that demand deep penetration welds. Operational expenses include maintenance, energy consumption, and specialized infrastructure. These factors contribute to the total cost of ownership.

| Cost Factor | Pulsed E-Beam Systems | Continuous E-Beam Systems |

|---|---|---|

| Operating Costs | Lower due to no chemicals | Lower due to no chemicals |

| Energy Efficiency | High | High |

| Infrastructure Costs | Smaller footprint | Smaller footprint |

| Regulatory Compliance Costs | Simpler | Simpler |

| Turnaround Time | Fast | Fast |

| Scalability | Modular | Modular |

Both pulsed and continuous systems offer high energy efficiency and fast turnaround times. Their modular design supports scalability for expanding welding operations. Facilities benefit from lower regulatory compliance costs and smaller infrastructure footprints compared to traditional methods.

Selection Guide

Decision Criteria

Selecting between pulsed and continuous electron beams depends on several technical and practical factors. Engineers and scientists often evaluate the following criteria:

- Application Requirements:

They identify the main goal, such as sterilization, welding, or microscopy. Pulsed beams suit tasks that need precise energy control. Continuous beams work best for processes that require steady energy delivery. - Material Properties:

They consider the thickness and sensitivity of the material. Thin or delicate materials benefit from pulsed beams. Thick or robust materials respond well to continuous beams. - Process Speed:

They assess the desired throughput. Pulsed beams allow rapid processing in short bursts. Continuous beams maintain consistent speed over longer periods. - Thermal Impact:

They analyze the risk of overheating. Pulsed beams minimize heat-affected zones. Continuous beams may increase thermal load. - Equipment Capabilities:

They check system compatibility and available features. Some machines only support one beam type.

Tip: Engineers should create a checklist of these criteria before choosing a beam type. This approach helps match technical needs with the right solution.

| Criteria | Pulsed Electron Beam | Continuous Electron Beam |

|---|---|---|

| Precision | High | Moderate |

| Throughput | Fast (bursts) | Consistent (steady) |

| Heat Control | Excellent | Good |

| Material Suitability | Thin, sensitive | Thick, robust |

| Equipment Complexity | Moderate | Simple |

Conclusion

Pulsed and continuous electron beams differ in energy delivery and application suitability. The table below highlights their technical and practical differences:

| Comparison Aspect | Pulsed Electron Beams | Continuous Electron Beams |

|---|---|---|

| Radiation Damage Mitigation | No significant advantage | No significant advantage |

| Correlation with Total Dose | Damage linked to total dose | Damage linked to total dose |

| Effect of Temperature | Lower temperature reduces damage | Lower temperature reduces damage |

| Viability for Damage Reduction | Not a viable solution | Not a viable solution |

Continuous beams remain the preferred choice for electron beam sterilization and welding due to their proven safety, reliability, and precise dosing. Pulsed beams offer advantages for applications needing controlled energy bursts.

To select the right beam type, experts recommend:

- Match vacuum type to material characteristics.

- Align equipment parameters with material thickness and type.

- Optimize material compatibility and process controls for best results.

FAQ

What Is the Main Advantage of Pulsed Electron Beams?

Pulsed electron beams deliver high peak power in short bursts. This feature allows precise control over energy delivery. Engineers use this advantage for applications that require minimal heat-affected zones and accurate material processing.

When Should Continuous Electron Beams Be Used?

Continuous electron beams provide a steady energy stream. They work best for processes that need uniform heating, such as welding or sterilization. Operators choose continuous beams for consistent results and reliable performance in industrial environments.

How Do Electron Beams Compare to Lasers in Cutting and Marking?

Both electron beams and lasers can perform cutting and marking. Lasers often offer more flexibility for non-metal materials. Electron beams excel in high-precision metal work. The choice depends on the material and the required accuracy.

Can Electron Beams Be Used For Testing Materials?

Yes, electron beams play a role in testing. Scientists use them to analyze material properties, detect flaws, and study microstructures. This method provides detailed information about the internal structure of metals and other materials.

What Safety Measures Are Needed During the Electron Beam Process?

Operators must use shielding to block radiation. Facilities require strict safety protocols. Regular monitoring ensures safe operation. Proper training helps prevent accidents during the process.