E-beam crosslinking creates high-performance hydrogel wound dressing by using a focused electron beam to bond polymers. This process advances wound care by producing dressings with strong, flexible structures. E-beam technology avoids toxic chemicals and ensures safety for patients. Medical teams rely on these dressings for their reliable performance and built-in sterilization, which traditional methods cannot match.

Key Takeaways

- E-beam crosslinking creates strong and flexible hydrogel dressings without toxic chemicals, ensuring safety for patients.

- Hydrogel dressings maintain a moist environment, promoting faster wound healing and reducing pain during dressing changes.

- The e-beam process sterilizes dressings during manufacturing, eliminating the need for additional sterilization steps.

- Customization of hydrogel properties is possible by adjusting polymer types and irradiation settings, allowing for tailored medical solutions.

- E-beam hydrogel dressings are environmentally friendly, producing minimal waste and containing no harmful residues.

E-Beam Crosslinking Process

Electron Beam Technology

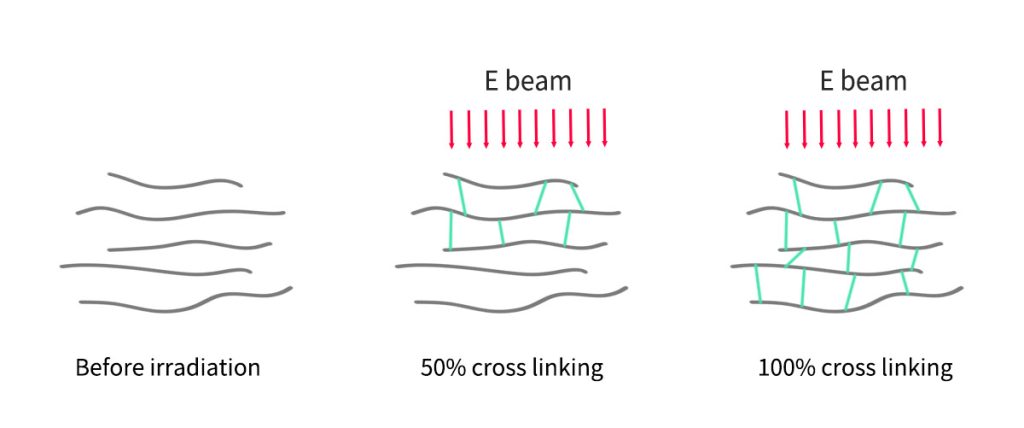

Electron beam technology plays a crucial role in the synthesis of hydrogels for medical dressings. Engineers use electron beam irradiation equipment to deliver a focused stream of high-energy electrons onto polymer materials. This process initiates the formation of reactive species, such as hydroxyl radicals, which interact with polymer chains. These interactions break existing bonds and create macroradicals. The macroradicals recombine, forming new bonds that result in a stable, interconnected polymer network. This network gives hydrogel dressings their strength and flexibility.

E-beam crosslinking eliminates the need for toxic chemical additives. The electron beam not only drives the synthesis of hydrogels but also sterilizes the material during processing. Medical teams benefit from dressings that are safe, residue-free, and ready for immediate use.

Steps in Hydrogel Manufacturing

The synthesis of hydrogels using e-beam crosslinking involves several engineering steps. Each step contributes to the final properties of the dressing.

- Preparation: Technicians extrude or mold the polymer material into the desired shape. Sometimes, they apply thermal preheating to optimize the material for irradiation.

- Irradiation: The shaped polymer enters the electron beam irradiation equipment. The equipment exposes the material to a controlled dose of high-energy electrons, typically ranging from 7.5 kGy to 12.5 kGy.

- Crosslinking: The energy from the electron beam breaks chemical bonds within the polymer chains. New bonds form between chains, creating a robust hydrogel network.

- Cooling and Finishing: The crosslinked material may undergo additional thermal treatment. Technicians then process the hydrogel to achieve the desired final properties.

Researchers can tailor the properties of hydrogel dressings by adjusting the formulation and irradiation parameters. For example, adding lavender oil or surfactants changes the swelling capacity, elasticity, and mechanical strength. The interaction between additives like Tween 80 and the polymer matrix produces a softer, more flexible hydrogel. By controlling the crosslinking density, engineers ensure the hydrogel meets specific medical requirements.

The synthesis of hydrogels using e-beam crosslinking provides built-in sterilization. The electron beam destroys bacteria and other contaminants during the process. This feature makes e-beam crosslinking ideal for medical applications, where safety and purity are essential.

Hydrogel Dressings in Medicine

Hydrogel Properties

Hydrogels serve as essential materials in wound healing. Scientists define hydrogels as networks of hydrophilic polymers that contain a high percentage of water. This structure allows hydrogel wound dressing to maintain a moist environment at the wound site. Moisture supports autolysis, which helps remove dead tissue and promotes wound healing. Hydrogels also provide a cooling effect, which soothes the skin and reduces discomfort. The non-adherent nature of hydrogel wound dressing prevents sticking to the wound, making dressing changes less painful. Gas exchange occurs freely through the hydrogel, supporting healthy tissue growth.

Hydrogels offer several advantages for wound healing:

- Maintain a moist wound environment

- Promote autolysis of necrotic tissue

- Provide a cooling effect

- Allow for gas exchange

- Non-adherent to wound surfaces

- Composed of hydrophilic polymers and high water content

Medical Applications

Hydrogel wound dressing finds widespread applications in wound healing, especially in burn care. Hospitals and clinics use hydrogel wound dressing for burns, ulcers, and surgical wounds. These dressings account for a significant portion of the global market, valued at USD 3 billion. Hydrogel wound dressing absorbs exudate, keeps the wound moist, and can be shaped to fit different wound conditions. The non-adhesive properties reduce pain and allow medical staff to observe the wound without disturbing healing.

Hydrogel wound dressing formulations often include polymers such as polyethylene glycol (PEG), polyethylene oxide (PEO), polyvinylpyrrolidone (PVP), collagen, gelatin, hyaluronic acid, alginate, chitosan, polyvinyl alcohol (PVA), methacryloyl-modified gelatin (GelMA), and fibrinogen. These components help create dressings with specific mechanical and biological properties for wound healing. Some hydrogel wound dressing products contain therapeutic additives like lavender oil, which can provide antibacterial effects and enhance wound healing. The flexibility in formulation supports a wide range of applications in wound dressing, from minor cuts to severe burns.

Traditional vs. E-Beam Crosslinking

Physical and Chemical Methods

Manufacturers have used physical and chemical crosslinking methods for decades to produce hydrogels. Physical crosslinking relies on non-covalent interactions, such as hydrogen bonding and ionic forces, to create a three-dimensional network. This approach offers reversibility and recyclability, making it suitable for adaptable applications. Chemical crosslinking forms strong, permanent bonds between polymer chains. However, chemical methods often require toxic agents, such as glutaraldehyde, glyoxal, formaldehyde, and epoxy compounds. These chemicals can leave harmful residues in the final hydrogel wound dressing.

Traditional chemical crosslinking methods may result in inconsistent mechanical properties and variable degradation rates. Many physical and chemical techniques struggle with scalability and reproducibility, especially in industrial settings.

| Crosslinking Method | Bond Strength | Stability | Environmental Impact |

|---|---|---|---|

| Physical | Weaker, unstable bonds | Degrades over time | More environmentally friendly |

| Chemical | Strong, permanent bonds | Better mechanical strength | Toxic chemicals may leach out |

| E-beam | Strong, permanent bonds | High stability, no toxins | Environmentally friendly, no leaching |

E-Beam Advantages

E-beam crosslinking uses electron beam radiation to create strong, permanent bonds in hydrogels without toxic additives. This process sterilizes dressings during manufacturing, eliminating the need for separate sterilization steps. E-beam crosslinking provides precise control over polymer network formation, allowing manufacturers to tailor properties such as swelling, elasticity, and degradation rate.

- E-beam crosslinking offers several benefits:

- No toxic chemical residues

- Enhanced antimicrobial and antioxidant activity

- Superior wound healing performance

- Improved control over active ingredient incorporation

- Custom shapes and sizes for hydrogel wound dressing

| Performance Metric | E-Beam Crosslinked Hydrogels | Traditional Hydrogels |

|---|---|---|

| Antimicrobial Activity | Enhanced | Standard |

| Controlled Release | Improved | Limited |

| Wound Healing Performance | Superior | Moderate |

| Antioxidant Activity | Remarkable | Not specified |

| Anti-inflammatory Properties | Enhanced | Not specified |

Manufacturers can adjust exposure time, voltage, and amperage during e-beam processing to achieve desired crosslinking density. E-beam technology supports the incorporation of medications and skin care ingredients, making hydrogel dressings highly customizable for different medical needs.

Performance of E-Beam Hydrogel Dressings

Safety and Sterilization

E-beam crosslinking produces hydrogel wound dressing that is non-toxic and residue-free. The process creates biocompatible and biodegradable dressings that do not contain harmful chemicals. Medical teams value these dressings for their built-in sterilization. The electron beam destroys bacteria and other contaminants during manufacturing, which ensures high antibacterial performance. Hospitals rely on hydrogel wound dressing for its ability to maintain moisture and provide a safe healing environment.

- Typical sterilization rates for e-beam crosslinked hydrogels:

- Hydrogels with 0.1% PEO show gel fraction below 60% at doses lower than the sterilization dose.

- Systems with PEO concentrations of 0.25–0.5% achieve gel fraction higher than 75%.

- Systems with PEO concentrations of 0.5–1% have gel fraction around 72%.

Hydrogel wound dressing supports the emerging field of tissue engineering by offering biocompatible and antibacterial properties. The high water content in these dressings helps maintain moisture, which is essential for wound healing. The moisture retention capability of e-beam crosslinked hydrogel wound dressing allows wounds to stay hydrated and protected from infection.

Tailored Properties

Researchers can adjust the formulation of hydrogel wound dressing to meet specific medical needs. By changing the concentration of PEO or other polymers, they control the mechanical strength, swelling behavior, and moisture retention capability. Higher PEO concentrations increase cross-link density and improve biocompatible and antibacterial performance. These dressings remain stable for more than 72 hours in physiological pH buffers and reach equilibrium after 25 hours.

| Property | Effect of PEO Concentration |

|---|---|

| Cross-link Density | Increased with higher PEO concentrations |

| Swelling Behavior | Lower at low PEO concentrations |

| Elastic Modulus (G′) | Higher values (9.8 kPa) indicating elastic behavior |

| Viscous Modulus (G″) | Lower values (0.2 kPa) |

| Stability | Greater than 72 h in physiological pH buffers |

| Equilibrium Time | Reached after 25 h |

| Average Molecular Weight (Mc) | Strongly dependent on PEO concentration |

| Mesh Size (ξ) | Affected by PEO concentration and absorbed dose |

Hydrogel wound dressing demonstrates excellent moisture retention and antibacterial activity. The dressings absorb moisture and swell up to 2.2 grams, which increases their volume by about 820%. The moisture retention capability is calculated using the equation: Moisture retention capability (%) = (Wd/Ww) × 100. Gel fraction is determined by Gel fraction (%) = (We/Wo) × 100.

Hydrogel wound dressing provides biocompatible, biodegradable, and antibacterial solutions for wound care. The ability to tailor crosslinking and formulation ensures optimal moisture retention and healing.

Conclusion

E-beam crosslinking offers many advantages for hydrogel dressings. The process ensures biocompatibility, non-toxicity, and sterility while allowing precise control over hydrogel properties.

| Key Benefit | Description |

|---|---|

| Biocompatibility | Prevents microbial infection |

| Non-toxicity | Uses only safe materials |

| Sterility | Produces sterile dressings |

| Customizability | Adjusts structure and properties as needed |

| Environmental Friendliness | Creates pure, eco-friendly materials |

E-beam technology reduces pore size more effectively than traditional methods, leading to improved healing. Future hydrogel innovations may include sprayable forms, smart sensors, and nanomaterial integration, which will further enhance wound care.

FAQ

What Is E-Beam Crosslinking?

E-beam crosslinking uses high-energy electrons to bond polymer chains in hydrogels. This method creates strong, sterile dressings without toxic chemicals. Hospitals prefer this process for its safety and reliability.

How Does E-Beam Crosslinking Improve Hydrogel Safety?

E-beam crosslinking eliminates chemical residues and sterilizes the hydrogel during production. Patients receive dressings that reduce infection risk and avoid allergic reactions. Medical teams trust these dressings for sensitive wounds.

Can Hydrogel Dressings Be Customized with E-Beam Technology?

Researchers adjust polymer types, concentrations, and irradiation settings to create dressings with specific properties. E-beam technology allows for custom shapes, sizes, and the addition of therapeutic ingredients.

What Types of Wounds Benefit from E-Beam Hydrogel Dressings?

Doctors use e-beam hydrogel dressings for burns, ulcers, surgical wounds, and chronic injuries. These dressings maintain moisture, support healing, and reduce pain during dressing changes.

Are E-Beam Hydrogel Dressings Environmentally Friendly?

E-beam hydrogel dressings contain no toxic chemicals and produce minimal waste. Manufacturers use safe materials and energy-efficient processes. Hospitals choose these dressings for their eco-friendly benefits.