A multi-level safety interlock system in electron beam irradiation equipment uses several layers of safety measures to prevent hazardous operations and protect users. This safety control system addresses machine safety concerns by combining physical, electronic, and software safeguards. Engineers rely on international safety standards to guide risk assessment and system design. The following table highlights key standards:

| Standard | Description |

|---|---|

| ISO 12100 | Became the international standard for safety of machinery in 2001, crucial for machine safety. |

| ISO 14119 | Released in 2013, it provides guidelines for selecting and designing interlocking devices. |

These systems ensure compliance and support robust safety measures in high-risk environments.

Key Takeaways

- Multi-level safety interlock systems combine physical barriers, electronic controls, and software interlocks to protect users from radiation exposure.

- Engineers design these systems to meet international safety standards, ensuring compliance and enhancing safety in high-risk environments.

- Redundancy in interlock systems prevents single points of failure, providing continuous protection and maintaining reliable operation.

- Regular testing and operator training are essential to ensure the functionality of safety interlocks and to respond effectively to emergencies.

- Understanding the components and operation of interlock systems empowers operators to maintain safety and prevent hazardous situations.

Interlock System Components

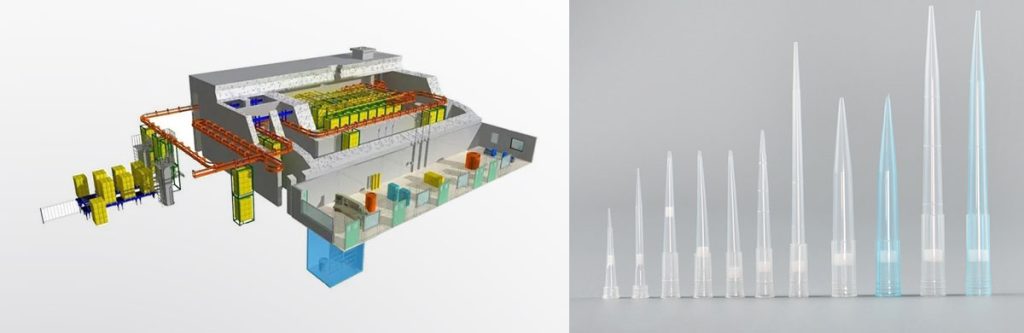

A multi-level safety control system in electron beam irradiation equipment relies on several interlocking devices. These components work together to prevent unsafe operation and unauthorized access. Each type of interlock addresses specific risks and forms a critical part of comprehensive safety solutions.

Physical Barriers

Physical barriers serve as the first line of defense in machine safety. These barriers block direct access to hazardous areas and absorb radiation produced during operation. Engineers select barrier materials based on the electron energy range and required shielding effectiveness. The table below summarizes common barrier types and their safety contributions:

| Barrier Material | Electron Energy Range | Thickness Requirement | Safety Contribution |

|---|---|---|---|

| Concrete | > 1 MeV | At least 3 m (10 ft) | Effective radiation shielding |

| Lead | < 1 MeV | Varies | Compact shielding for safety |

| Steel | < 1 MeV | Varies | Used in combination for safety |

Concrete barriers protect users from high-energy beams by absorbing radiation. Lead and steel barriers provide compact solutions for lower energy ranges. These physical safety-related parts ensure that only authorized personnel can access the irradiation chamber when the system is safe.

Electronic Controls

Electronic controls form the second layer of interlocking devices. These controls monitor door positions, emergency stops, and power supplies. Sensors and switches detect if a door is open or if a shield is not in place. The system interrupts operation if it detects any unsafe condition. Electronic controls also connect with alarms and warning lights to alert users about system status.

Redundant circuits and cross-checking mechanisms increase reliability. For example, dual-channel switches verify that both sensors agree on a door’s position. This redundancy prevents single-point failures and supports robust safety solutions. Electronic controls act as safety-related parts that enforce strict access and operational protocols.

Software Interlocks

Software interlocks provide a dynamic layer of protection. The software monitors system parameters and enforces operational limits. It checks for correct sequence of operations and verifies that all safety-related parts function as intended. If the software detects an unsafe condition, it initiates an immediate shutdown.

Historical incidents highlight the importance of reliable software interlocks. In some cases, over-reliance on software without hardware backup led to safety failures. For example, the Therac-25 system depended on software checks but lacked hardware interlocks to verify sensor status. This design flaw resulted in undetected faults and serious accidents. Modern electron beam irradiation equipment uses software interlocks in combination with hardware devices to ensure comprehensive safety.

Note: Effective interlock systems combine physical barriers, electronic controls, and software interlocks. This layered approach prevents unauthorized access, detects unsafe conditions, and responds quickly to hazards. Each component supports the overall safety control system and helps maintain compliance with international standards.

Safety Levels in Electron Beam Irradiation Equipment

Category 4 Architecture

Engineers design electron beam irradiation equipment with a hierarchical safety structure. Category 4 architecture represents the highest safety category level in machine safety standards. This architecture uses redundant interlock circuits and continuous monitoring to prevent hazardous failures. Each safety-related part must function independently, so a single fault cannot compromise the system. Operators rely on this robust design to ensure that equipment responds correctly to unsafe conditions. Category 4 architecture supports compliance with international safety standards and protects users from radiation exposure.

Monitoring Parameters

Operators monitor critical parameters to maintain safety during irradiation. These parameters include temperature, flow, and pressure. Real-time monitoring technologies provide immediate feedback and help prevent unsafe operation. The table below summarizes key monitoring systems used in electron beam irradiation equipment:

| Technology | Description |

|---|---|

| Beam Monitoring System (BMS) | Uses three integral ionization chambers and two multistrip ionization chambers for real-time beam position and flux monitoring. |

| Ionization Chambers (ICs) | Track beam flux online by integrating electrons with a uniform electric field. |

| Multistrip Ionization Chambers | Equipped with FPGA and DAQ, display real-time beam position and size, complete tests in 100 µs. |

Operators use these systems to detect abnormal conditions quickly. The interlock system responds to deviations by shutting down the beam or alerting personnel. This approach ensures that machine safety remains uncompromised.

Fault Tolerance

Fault tolerance plays a vital role in multi-level safety interlock systems. Engineers implement several strategies to maintain system reliability:

- Quality assurance testing verifies system performance.

- Error handling tests simulate faults and confirm proper system response.

- Interlocks trigger shutdowns when errors occur.

- Redundant devices and communication protocols eliminate single points of failure.

- Daily quality assurance checks confirm the functionality of the entire delivery system.

Operators encounter various faults, such as multileaf collimator failures, potentiometer issues, and RF driver errors. The interlock system mitigates these faults by turning off the beam or requiring part replacement. Minor interlocks alert operators to conditions that affect operation, allowing quick resolution. Collision detection systems, such as LaserGuard, prevent accidents and enhance safety.

Interlock Operation and Response

Detection and Shutdown

The interlock system in electron beam irradiation equipment operates through a precise sequence of detection and response steps. Operators initiate the process by selecting the desired radiation type at the control panel. The system then verifies that all interlocking devices, such as door switches and accessory sensors, are in the correct state. If any device signals an unsafe condition, the equipment halts operation immediately.

A typical workflow includes:

- The operator selects the radiation type.

- The system checks room conditions and accessory fittings.

- Interlocking devices confirm that only the selected radiation can be emitted.

- The system monitors critical parameters, such as bending magnet current and dose rate.

- If any parameter deviates from safe limits, the system triggers an automatic shutdown.

The table below summarizes how the interlock system detects unsafe conditions and initiates shutdown procedures:

| Requirement | Description |

|---|---|

| Interlock System | Ensures that the equipment can emit only the selected type of radiation. |

| Condition Agreement | Prevents irradiation if treatment room conditions do not match control panel settings. |

| Electron Applicators | Prevents x-ray irradiation when electron applicators are fitted. |

| Accessory Fitting | Prevents electron beam irradiation when x-ray therapy accessories are fitted. |

| Bending Magnet Current | Terminates irradiation if current varies by more than 10% of normal value. |

| Gantry Movement | Terminates irradiation if the gantry moves during stationary beam therapy or stops unexpectedly. |

| Dose Rate Variation | Terminates irradiation if dose rate varies by more than 20% of preselected value. |

| Radiation Selection | Ensures irradiation is only possible after selecting the type of radiation at the control panel. |

These steps ensure that machine safety remains uncompromised. The interlock system acts quickly to prevent hazardous exposure, relying on both hardware and software interlocking devices.

Emergency Protocols

Emergency protocols form a critical part of the safety framework in electron beam irradiation equipment. Operators must follow strict procedures to protect users and maintain compliance with safety standards. The system enforces several emergency measures:

| Requirement | Description |

|---|---|

| Primary Barriers | All areas struck by the useful beam must have primary barriers. |

| Secondary Barriers | Areas without primary barriers must have secondary barriers. |

| Communication | Continuous two-way communication between patient and operator is required. |

| Observation | Operators must be able to continuously observe the patient during irradiation. |

| Interlocks | All entrance doors must be closed before treatment can start; if interrupted, the machine cannot be restarted without manual action. |

| Emergency Power Cutoff | At least one emergency power cutoff switch must be present in the treatment room to terminate all equipment power. |

| Safety Interlocks | Any defect in the safety interlock system must prevent or terminate operation of the therapy equipment. |

Operators rely on these protocols to respond to emergencies. For example, if a door opens during irradiation, the interlock system halts the beam and requires manual intervention before restarting. Emergency power cutoff switches allow immediate shutdown of all equipment power in critical situations. Continuous observation and communication ensure that any incident receives a rapid response.

Tip: Regular training and drills help operators respond effectively to emergencies and reinforce the importance of safety protocols.

Redundancy

Redundancy enhances the reliability of multi-level safety interlock systems. Engineers design these systems with multiple independent interlocking devices and monitoring subsystems. This approach ensures that a single failure does not compromise overall safety.

The beam monitoring system (BMS) demonstrates this principle. It consists of three integral ionization chambers and two multistrip ionization chambers. The BMS for each treatment line divides into two completely independent subsystems. This design reduces risk during treatment and meets international safety requirements.

| Component | Description |

|---|---|

| BMS | Composed of three integral ionization chambers (ICs) and two multistrip ionization chambers (MSICs). |

| Redundancy | The BMS for each treatment line is divided into two completely independent subsystems for redundancy to reduce risk during treatment and meet IEC requirements. |

Additional redundancy measures include:

- All interlocks and safety features undergo testing during manufacturer acceptance procedures.

- Equipment manufactured after July 9, 1997, must have at least two independently powered integrating dose meters.

- The design ensures that malfunctioning of one system does not affect the functioning of the other. Any common failure will terminate or prevent irradiation.

Redundant interlocking devices and monitoring systems provide a robust defense against unexpected faults. This layered approach supports the highest standards of machine safety and ensures continuous protection for users.

Benefits

Enhanced Safety

Multi-level safety interlock systems provide robust protection for operators working with electron beam irradiation equipment. These systems use interlocking devices to prevent unauthorized access and ensure only trained personnel can operate the equipment. Operators can interrupt irradiation and equipment movement at any time from their control position. The interlock system ensures irradiation only occurs when all safety conditions are met, such as correct radiation type and energy selection. The following table highlights key safety solutions that improve safety for users:

| Requirement | Description |

|---|---|

| Unauthorized Use Prevention | A locking device must be provided to prevent unauthorized use of the x-ray system. |

| Operator Control | It must be possible to interrupt irradiation and equipment movements at any time. |

| Interlock System Functionality | An interlock system is required to ensure correct conditions before irradiation can occur. |

Operators benefit from these safety solutions, which reduce the risk of accidental exposure and support machine safety.

Compliance

Manufacturers design multi-level safety interlock systems to meet strict international standards. These systems help facilities comply with regulations by enforcing proper use of interlocking devices and safety protocols. Regular testing and documentation ensure that equipment remains in line with industry requirements. Compliance with standards such as ISO 12100 and ISO 14119 demonstrates a commitment to safety and quality. Facilities that follow these guidelines can avoid penalties and maintain a safe working environment.

Reliability

Reliability stands as a core advantage of advanced safety solutions. Engineers implement daily and annual tests to verify the performance of interlocking devices. The table below outlines the testing schedule that supports system reliability:

| Frequency | Test Description |

|---|---|

| Daily | Check the functionality of the door interlock to ensure the radiation beam terminates if the door is opened. |

| Annually | Test the door’s safe operation when staff and patients enter/exit, and check emergency opening options. |

| Daily | Check a single anti-collision device for system function, rotating through each system on subsequent days. |

Common reliability issues include failure or bypassing of interlock facilities and the need for regular testing. Facilities address these issues by scheduling routine checks, providing operator training, and designing systems with redundancy and fail-safe features. These practices improve safety and ensure that electron beam irradiation equipment operates without interruption.

Conclusion

Multi-level safety interlock systems in electron beam irradiation equipment protect users and ensure reliable operation. These systems use layered safeguards to meet strict industry standards. Facilities face challenges during implementation, such as technical difficulties in beam control and the need for robust dosimetry systems.

| Challenge | Description |

|---|---|

| Beam Control | Technical difficulties in controlling the beam for safe and precise delivery of FLASH radiotherapy. |

| Robust Dosimetry Systems | Need for high temporal resolution systems for real-time monitoring, as conventional systems are limited. |

| Stability and Precision Delivery | Issues with achieving stable and precise delivery, especially during initial pulses, leading to underdosing. |

By addressing these challenges, facilities maintain best practices and uphold the highest level of safety.

FAQ

What Is the Purpose of a Multi-Level Safety Interlock System?

A multi-level safety interlock system protects users from radiation exposure and equipment hazards. It uses physical, electronic, and software safeguards to prevent unsafe operation. Facilities rely on these systems to meet international safety standards and maintain reliable performance.

How Do Physical Barriers Improve Safety?

Physical barriers block access to hazardous areas and absorb radiation. Engineers select materials like concrete, lead, or steel based on the electron energy range. These barriers ensure only authorized personnel can enter the irradiation chamber when conditions are safe.

Why Is Redundancy Important in Interlock Systems?

Redundancy ensures that a single failure does not compromise safety. Engineers design systems with multiple independent interlocks and monitoring devices. This approach provides continuous protection and meets strict industry requirements for reliability.

What Happens If an Interlock Detects an Unsafe Condition?

The system immediately halts irradiation and alerts operators. Equipment cannot restart until the unsafe condition is resolved and verified. This rapid response prevents accidental exposure and supports safe operation.

Which Standards Govern Safety Interlock Systems for Electron Beam Equipment?

Facilities follow standards such as ISO 12100 and ISO 14119. These guidelines specify requirements for machine safety and interlocking devices. Compliance demonstrates a commitment to operator protection and quality assurance.