Electron beam accelerators demand careful attention to both foundation and utility requirements. Structural integrity supports heavy machinery, while electrical systems deliver stable power. Operators must install efficient cooling and ventilation systems to maintain safe temperatures. Safety protocols, such as shielding and emergency controls, protect personnel and equipment. Proper planning and compliance with regulations ensure reliable and secure operation.

Key Takeaways

- Ensure the foundation can support heavy machinery. Aim for a load-bearing capacity of at least 250 psf to prevent structural failures.

- Implement both passive and active vibration isolation systems. This combination protects sensitive equipment from disruptive vibrations.

- Design effective shielding to protect personnel from radiation. Use concrete or Cerrobend based on the energy levels of the electron beam.

- Plan utility requirements carefully. A robust electrical supply and efficient cooling systems are essential for safe and effective operation.

- Follow regulatory standards closely. Compliance ensures safety and builds trust with customers and regulatory bodies.

Foundation for Electron Beam Accelerators

Load-Bearing Capacity

Electron beam accelerators and electron beam irradiation equipment place significant demands on building foundations. Floors must support heavy machinery and associated infrastructure. Engineers recommend a maximum uniformly distributed load of 250 pounds per square foot (psf) for these installations. Concentrated loads may reach 3,000 pounds. Light building loads range from 100 to 150 psf, while industrial buildings typically support 100 to 200 psf. Heavy loading can require up to 500 psf. The following table summarizes these values:

| Load Type | Capacity |

|---|---|

| Maximum uniformly distributed load | 250 psf |

| Maximum concentrated load | 3,000 lbs |

| Typical light building load | 100 to 150 psf |

| Industrial building load range | 100 to 200 psf |

| Heavy loading | 500 psf |

Proper planning ensures that the foundation meets these requirements and prevents structural failures.

Vibration Isolation

Vibration isolation plays a critical role in maintaining operational stability for electron beam accelerators. Passive vibration isolation systems, often pneumatic, reduce high-frequency vibrations. Active vibration isolation systems target low-frequency vibrations, especially in the 3-15 Hz range. Facilities often combine both systems to achieve optimal performance. The NIST-A criterion specifies a root mean square displacement of 1 μin (25 nm) for frequencies below 20 Hz. VC criteria, labeled VC-A through VC-G, provide additional standards for vibration-sensitive environments. These criteria help accelerator facilities maintain the necessary stability for precise operations.

Tip: Combining passive and active vibration isolation systems offers comprehensive protection against disruptive vibrations.

- The NIST-A criterion is designed for vibration-sensitive environments, specifying a root mean square displacement of 1 μin (25 nm) for frequencies below 20 Hz.

- VC criteria consist of one-third octave band velocity spectra labeled VC-A through VC-G, which have been modified over time to adapt to various research needs.

- These criteria are essential for ensuring that accelerator facilities meet the necessary standards for vibration isolation.

Shielding

Shielding protects personnel and equipment from X-rays produced by electron beam accelerators. Shielding design must consider the worst-case energy and current to ensure safety. Calculations often use monitor unit-based weekly workload, and studies show that radiation exposure distribution remains consistent across energy levels. For industrial installations, experts recommend three meters of concrete or earth as a standard barrier. Cerrobend is another shielding material, with thickness requirements varying by electron beam energy:

| Electron Beam Energy (MeV) | Recommended Cerrobend Thickness (mm) |

|---|---|

| 4 | 2 |

| 6 | 2 |

| 8 | 4 |

| 9 | 4 |

| 10 | 4 |

| 12 | 6 |

| 15 | 6 |

| 16 | 10 |

| >20 | >20 |

Shielding requirements also depend on regulatory standards. For example, the ALBA Synchrotron uses FLUKA simulations to ensure public dose rates remain below 0.5 μSv/h during operation.

Space Planning

Space planning ensures safe and efficient operation of electron beam accelerators. Facilities must allocate enough room for equipment, maintenance, and safety zones. Regulatory standards require a Safety Assessment Document (SAD) for accelerators operating above 10 MeV. The Accelerator Safety Envelope (ASE) defines safety boundaries and must receive approval from the Department of Energy. The Unreviewed Safety Issue (USI) process identifies and addresses new hazards. An Accelerator Readiness Review (ARR) is necessary before commissioning and routine operations.

| Requirement | Description |

|---|---|

| Safety Assessment Document (SAD) | Required for accelerators operating above 10 MeV to assess safety risks. |

| Accelerator Safety Envelope (ASE) | Must be DOE-approved to define safety boundaries. |

| Unreviewed Safety Issue (USI) Process | Necessary for identifying and addressing new hazards. |

| Accelerator Readiness Review (ARR) | Required before commissioning and routine operations. |

Careful planning of space and layout supports compliance and enhances safety for all personnel.

Utility Requirements

Electrical Supply

Electron beam accelerators require a robust electrical supply to operate safely and efficiently. The electrical hookup power typically exceeds three times the rated beam power. For example, in the CONNEX project, a single cavity needs 200 W of RF power for a 10-mA beam through a 20-kV gap. Each cavity may require up to 450 W of RF power, with the nominal minimum output of the HEMT at 350 W, often producing 450 W at 50 V DC.

Key features of recommended electrical supply configurations include:

| Feature | Details |

|---|---|

| Voltage Range | -10 kV to -60 kV |

| Ripple | Ultra-low |

| Stability | High stability |

| Programmable Channels | Four floating channels |

| Acceleration Voltage | Up to -160 kV |

| Temperature Coefficient | 25 ppm/°C (optional 10 ppm/°C) |

| Isolation | Fiber-optic galvanic isolation |

| Custom Configuration | Available with additional output |

A stable and programmable electrical system supports precise control and safety for the accelerator.

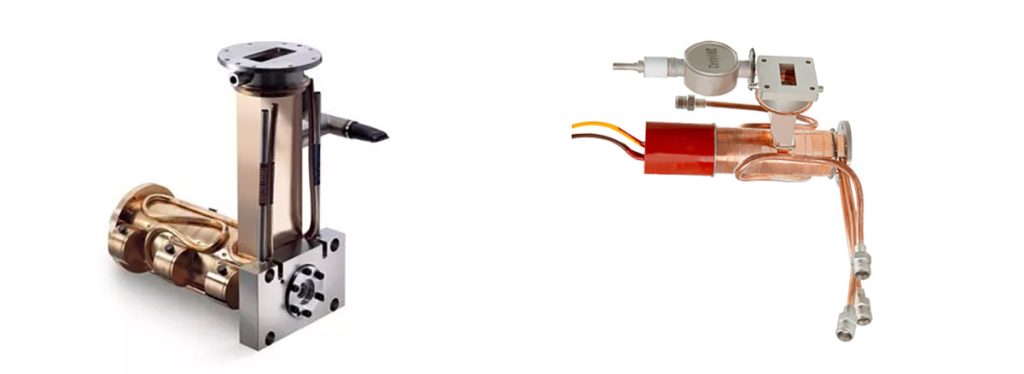

Cooling Systems

Effective cooling systems are essential for maintaining the performance and longevity of electron beam accelerators. These systems often use chilled water and consume 20-30% of the cooling power rating in electrical energy. Custom liquid cooling systems optimize temperature stabilization and control. Facilities must manage thermal loads for critical components such as the tungsten target, waveguide, and acceleration chamber.

Best practices for cooling include:

- Implementing custom liquid cooling to maintain temperature consistency within ±0.5°C.

- Using recirculating coolant to keep components at a set-point temperature.

- Designing plug-and-play systems for easy maintenance and service.

Note: Liquid cooling systems provide greater efficiency than air-based systems, especially for high-power electron applications.

Ventilation

Proper ventilation ensures safe air quality in accelerator rooms. Facilities should provide a minimum of 6 air changes per hour (ACH) for laboratories handling hazardous materials. Continuous exhaust ventilation helps remove contaminants and maintain a safe environment.

Common air filtration systems include:

- HEPA filters: Capture at least 99.97% of airborne particles 0.3 microns or larger.

- ULPA filters: Capture at least 99.9995% of particles 0.12 microns or larger.

- Activated carbon filters: Adsorb volatile organic compounds and hazardous gases.

These filtration systems are often used together to enhance air purification and protect both personnel and sensitive equipment.

Air and Vacuum Systems

Compressed air and vacuum systems play a vital role in the operation of electron beam accelerators. Turbomolecular vacuum pumps, often radiation-hardened, support safe operation over long distances. Dry backing pumps, which are fluorine- and oil-free, suit ultra-high vacuum (UHV) systems. Mobile turbomolecular units allow for fast evacuation of beamline segments.

| Component Type | Specifications |

|---|---|

| Turbomolecular vacuum pumps | Radiation-hardened, remote electronics, up to 120 m operation |

| Dry backing pumps | Multi-stage roots, fluorine- and oil-free, NEG-compatible, UHV suitable |

| Mobile turbomolecular vacuum units | Portable, fast evacuation for beamline segments and UHV chambers |

| Measurement tools | Passive total pressure gauges, residual gas analyzers |

| Custom UHV chambers and components | Metal seals, low-desorption materials, acceptance-tested for cleanliness |

Facilities should monitor vacuum pressure and cryo temperature regularly, log values for trend analysis, and defrost cryopumps as needed. Vacuum requirements vary by accelerator type and energy. Higher energy systems need more robust vacuum to prevent oxidation and maintain efficiency, while lower energy systems have less stringent needs.

Data Lines

Reliable data lines are crucial for monitoring and controlling accelerator operations. Facilities must implement virus prevention policies to protect against data corruption. Synchronization between the treatment planning system and the actual delivery data ensures consistency and safety. Automated integrity tests, such as checksums, help verify all records before use.

Tip: Regularly compare the treatment database with the intended plan to detect errors and maintain data integrity.

Careful planning of utility requirements supports safe, efficient, and reliable operation of electron beam accelerators.

Safety and Compliance

Regulatory Standards

Regulatory standards play a vital role in the safe operation of electron beam accelerators. Authorities in major markets, such as the U.S. FDA, European Food Safety Authority (EFSA), and FSSAI in India, set strict guidelines for food safety, healthcare, and industrial applications. These standards focus on microbial control, chemical residue limits, and shelf-life assurance. Companies must comply with evolving policies to enter new markets and maintain credibility. Many organizations invest in quality assurance and work closely with regulatory bodies. International efforts aim to harmonize standards, making approval processes more efficient.

- Regulatory bodies influence technology adoption in food processing.

- Compliance with safety, radiation shielding, and environmental impact standards is essential.

- Harmonized standards support global deployment and market growth.

- Strict guidelines enhance credibility in healthcare and food sectors.

Meeting regulatory standards ensures safe operation and builds trust with customers and regulators.

Emergency Systems

Facilities use advanced emergency systems to protect personnel and equipment. Two main systems provide rapid response during emergencies:

| System | Description |

|---|---|

| Personnel Safety System (PSS) | Uses sensors, interlocks, warning devices, and PLCs to protect staff from radiation. Two autonomous chains detect faults and shut down equipment. |

| Machine Protection System (MPS) | Hardware-based system that shuts off the electron beam to prevent component damage. Includes trip signals and a Fast Shutdown feature. |

Best practices for emergency response include staff training, clear communication, regular drills, and defined roles. Facilities foster a safety culture where employees feel empowered to report concerns and participate in training.

Access Control

Access control technologies restrict entry to hazardous areas and protect personnel. Facilities use several systems to ensure only authorized staff can enter accelerator zones:

| Access Control Technology | Description |

|---|---|

| Safety Interlock System | Provides high reliability and fail-safe operation for controlling access. |

| Beamline Safety Interlock | Controls access to each beamline hutch based on shutter status. |

| Programmable Logic Controller | Links interlock components to stop machine operations reliably. |

| Multiplex Systems | Includes door keep systems, emergency buttons, and beam shutter systems tailored to hazard levels. |

Effective access control reduces risks and supports compliance with safety regulations.

Planning and Installation

Coordination

Successful installation of electron beam accelerators depends on close coordination with facility engineers. They review site conditions and assess structural requirements. Engineers work with project managers to schedule construction and equipment delivery. Communication between teams helps avoid delays and ensures that all technical specifications are met. Facility engineers also verify that electrical, cooling, and safety systems match the needs of the accelerator. Regular meetings allow teams to address challenges and adjust plans as needed.

Tip: Early involvement of facility engineers leads to smoother installation and fewer unexpected issues.

Scalability

Facilities must consider future scalability when designing accelerator installations. Expansion plans should include extra space for new equipment and upgrades. Technical support and spare parts must be available to maintain smooth operations. Compact designs help maximize limited space without sacrificing performance. Training programs prepare personnel to operate new systems safely and efficiently.

- Availability of technical support and spare parts

- Site preparation that assesses space, power supply, and shielding needs

- Compact designs for efficient use of area

- Training programs for safe and effective operation

Proper planning supports long-term growth and adaptability.

Maintenance Access

Maintenance access is essential for serviceability and safety. Engineers design layouts with clear pathways to critical components. Removable panels and modular systems simplify repairs and upgrades. Facilities must provide enough space for technicians to work comfortably and safely. Scheduled maintenance checks help prevent equipment failures and extend the life of the accelerator.

| Maintenance Feature | Benefit |

|---|---|

| Removable panels | Easy access for repairs |

| Modular systems | Quick replacement of parts |

| Clear pathways | Safe technician movement |

| Scheduled checks | Prevents unexpected failures |

Facilities that prioritize maintenance access reduce downtime and improve reliability.

Conclusion

Electron beam accelerators need strong foundations, reliable utilities, and strict safety measures. Facility managers should use a checklist to review load-bearing capacity, vibration isolation, shielding, electrical supply, cooling, ventilation, and access control.

Consulting with experts and following regulatory standards improves safety and performance.

Careful planning and compliance help facilities operate accelerators safely and efficiently.

FAQ

What Is the Typical Lifespan of an Electron Beam Accelerator?

Most electron beam accelerators operate for 10 to 20 years with regular maintenance. Facilities that follow strict service schedules and replace worn parts can extend equipment life. Proper cooling and vibration control also help maintain performance.

How Much Space Does an Accelerator Installation Require?

A standard industrial accelerator setup needs at least 1,000 to 2,000 square feet. This space includes the accelerator, shielding, utilities, and safety zones. Facilities should plan for future expansion and easy maintenance access.

Why Is Vibration Isolation Important for Accelerators?

Vibration isolation keeps the accelerator stable. Even small vibrations can affect beam quality and equipment accuracy. Facilities use both passive and active systems to reduce vibration and protect sensitive components.

What Safety Measures Protect Personnel During Operation?

Facilities use shielding, emergency shutdown systems, and access controls to protect staff. Regular training and safety drills prepare personnel for emergencies. Warning signs and interlocks prevent unauthorized entry into hazardous areas.

Can Facilities Upgrade Accelerators After Installation?

Yes, many accelerators support upgrades. Facilities can add new modules, improve control systems, or expand capacity. Planning for scalability during the initial design makes future upgrades easier and more cost-effective.