Operators often face the challenge of delivering the correct electron beam dose during processing. Scan width and conveyor speed play a direct role in this control. Precise adjustment ensures that each product receives the intended dose. Quality depends on accurate dosing because it directly affects both the effectiveness of sterilization and the preservation of product characteristics. Safety standards require that the process eliminates harmful pathogens while maintaining product integrity. Consistent dosing supports repeatable outcomes, which is vital for both quality and safety. Proper control not only improves quality but also guarantees safety for end users and operators.

Key Takeaways

- Adjust scan width to match product size for even dose distribution. This prevents overscan losses and ensures effective sterilization.

- Control conveyor speed to fine-tune exposure time. Slower speeds increase dose, while faster speeds decrease it, impacting product quality.

- Regularly verify dose measurements with calibrated dosimeters. This ensures compliance with safety standards and maintains consistent results.

- Balance scan width, conveyor speed, and beam current for optimal dose delivery. Adjusting one parameter often requires changes to others.

- Conduct routine maintenance and audits to ensure equipment reliability. This supports consistent electron beam sterilization and product safety.

Electron Beam Dose Basics

What Is Electron Beam Dose?

Electron beam dose refers to the amount of energy that a material absorbs when exposed to an electron beam during irradiation. In industrial settings, operators measure this energy as the absorbed dose. The absorbed dose serves as the standard unit for quantifying how much energy a product receives. This measurement is essential for determining if the process meets both functional and regulatory requirements. Most industries use the absorbed dose measured in water because many products, such as medical devices and food, have similar absorption properties. This approach ensures accurate and consistent results across different materials.

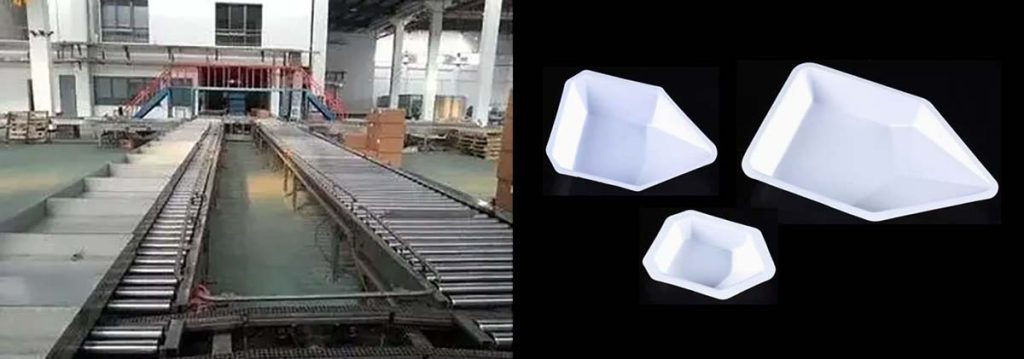

A typical electron beam system delivers energy by scanning a focused beam across the width of a conveyor. The dose depends on several factors, including beam current, scan width, and conveyor speed. Operators monitor these parameters to ensure the correct dose reaches every part of the product.

Why Dose Matters?

The electron beam dose plays a critical role in product quality and safety. If the dose falls below the required minimum, sterilization may not be effective, leaving harmful microorganisms on the product. If the dose exceeds the maximum, the product may suffer damage or lose its intended properties. Regulatory agencies set strict guidelines for minimum and maximum doses to protect consumers and maintain product performance.

Tip: Always verify dose measurements with calibrated dosimeters to ensure compliance and consistency.

Proper dose control supports repeatable outcomes. Manufacturers rely on precise dosing to deliver consistent results from batch to batch. This consistency builds trust with customers and meets industry standards. Accurate dose delivery also reduces waste and improves operational efficiency.

Key Parameters in Electron-Beam Irradiation

Scan Width Explained

Scan width defines the area that the electron beam covers as it moves across the conveyor. In electron-beam irradiation, operators set the scan width on the electron beam irradiation equipment to match the product size. A wider scan width helps distribute the dose more evenly across the product surface. Experiments using dosimeters have shown that electron beam irradiation can achieve dose uniformity within 2% across the diameter of a calorimeter disk. This high level of uniformity means that products receive consistent treatment during electron beam irradiation. Operators must also consider overscan correction. If the scan width extends beyond the product edges, some energy may not reach the target, leading to dose loss. Adjusting the scan width to fit the product and correcting for overscan ensures accurate electron beam irradiation.

Conveyor Speed Explained

Conveyor speed controls how fast products move through the electron beam irradiation. Electron beam irradiation equipment allows precise adjustment of conveyor speed, often between 1 and 30 feet per minute. Slower conveyor speeds increase the exposure time, resulting in a higher absorbed dose during electron beam irradiation. Faster speeds reduce exposure, lowering the dose. Operators use conveyor speed to fine-tune the dose for each product type. Consistent conveyor speed ensures that every item receives the same electron beam irradiation, which is essential for process repeatability and product quality.

Note: Operators should regularly check conveyor speed settings to maintain consistent electron beam irradiation results.

Parameter Interaction

The final dose delivered during electron beam irradiation depends on the interaction between scan width, conveyor speed, and beam current. Electron beam irradiation equipment allows operators to adjust these parameters for optimal results. The absorbed dose increases with higher beam current and decreases with faster conveyor speed. The following table summarizes these relationships:

| Parameter | Description |

|---|---|

| D | Absorbed dose (kGy) |

| I | Beam current (mA) |

| V | Line speed (m/min) |

| W | Irradiation width (cm) |

| K | Constant (equipment-specific) |

Operators must balance these factors during electron beam irradiation. Adjusting one parameter affects the others. For example, increasing the conveyor speed during electron beam irradiation requires a higher beam current or a narrower scan width to maintain the same dose. Understanding these interactions helps operators achieve precise and reliable electron beam irradiation for every product batch.

Dose Control Steps

Calculating Electron Beam Dose

Operators must calculate irradiation doses accurately to maintain quality and safety during processing. The electron beam dose depends on several process parameters, including scan width and conveyor speed. Operators use mathematical formulas to determine the correct irradiation doses for each product. The following table summarizes common formulas used in process control:

| Formula | Description |

|---|---|

| Δy = v / PRR | Displacement of a product point along the transverse direction within a time gap of two successive pulses. |

| D(x) = D1(d1) + D2(d2) + … + DN(dN) | Total dose at a point in a scan calculated by integrating the incremental dose from all pulses during the scan. |

| D(x) = (A / (σd√(2π))) * Σ (e^(-dn² / (2σ²))) | Alternative expression for total dose considering Gaussian distribution of dose. |

Operators begin by identifying the required irradiation doses for the product. They then select process parameters that will deliver the correct electron beam dose. Monitoring doses throughout processing ensures that the product receives the intended amount of ionizing radiation. Operators use dose measurements from calibrated dosimeters to verify that the calculated values match actual results. This step supports both quality and safety in every batch.

Adjusting Scan Width

Scan width adjustment plays a key role in process control. Operators set the scan width to match the product size, which helps achieve uniform irradiation doses across the entire surface. If the scan width is too wide, some of the ionizing radiation may miss the product, causing overscan losses. This reduces the electron beam dose and can compromise safety and quality.

To adjust scan width effectively, operators follow these steps:

- Measure the product width and determine the optimal scan width.

- Set the scan width on the irradiation equipment, ensuring it covers the product without excessive overscan.

- Use dose measurements to check for uniformity across the product surface.

- If monitoring doses reveal uneven distribution, fine-tune the scan width and repeat the process.

Tip: Always correct for overscan losses by adjusting the scan width to minimize wasted ionizing radiation and maintain consistent irradiation doses.

Proper scan width adjustment ensures that each product receives the correct electron beam dose, supporting both quality and safety during processing.

Adjusting Conveyor Speed

Conveyor speed directly affects irradiation doses during processing. Slower conveyor speeds increase exposure time, resulting in higher irradiation doses. Faster speeds reduce exposure, lowering the electron beam dose. Operators use conveyor speed as a primary process control tool to fine-tune irradiation doses for different products.

To adjust conveyor speed, operators:

- Identify the required irradiation doses for the product.

- Set the initial conveyor speed based on previous process parameters and dose measurements.

- Run a test batch and use monitoring doses to check if the electron beam dose meets quality and safety standards.

- Adjust the conveyor speed as needed, increasing or decreasing it to achieve the target irradiation doses.

Consistent conveyor speed helps maintain uniform processing and supports reliable process control. Operators should regularly verify conveyor speed settings to ensure ongoing quality and safety.

Balancing Parameters

Balancing process parameters is essential for effective process control in electron beam processing. Operators must consider scan width, conveyor speed, and other factors such as beam current to achieve the desired irradiation doses. Changing one parameter often requires adjustments to others to maintain the correct electron beam dose.

A typical balancing process includes:

- Reviewing dose measurements from recent processing runs.

- Adjusting scan width to optimize coverage and minimize overscan losses.

- Modifying conveyor speed to fine-tune irradiation doses.

- Monitoring doses throughout processing to ensure quality and safety.

- Recording all process parameters for future reference and continuous improvement.

Note: Effective process control relies on regular monitoring doses and prompt adjustments to process parameters. This approach ensures consistent quality and safety for every product batch.

Operators who balance process parameters carefully can deliver precise irradiation doses, maintain high product quality, and uphold strict safety standards. Continuous process control and dose measurements support reliable processing and help meet regulatory requirements for ionizing radiation applications.

Applications and Troubleshooting

Electron Beam Sterilization Scenarios

Operators use electron beam sterilization in many industries, including medical device sterilization and food processing. Each application requires careful adjustment of scan width and conveyor speed to achieve the correct dose. For example:

- Samples placed on the conveyor receive exposure based on set parameters.

- Operators control conveyor speed to deliver the defined electron beam sterilization dose.

- High doses sometimes require incremental adjustments to avoid damaging sensitive products.

Different materials respond uniquely to electron beam sterilization. Polymers may undergo cross-linking or chain scission, which changes their mechanical properties. Metals react differently, with their bulk properties influenced by the energy level of the electron beam. Operators must adjust parameters to optimize the effects for each product type.

| Process Variable | Impact On Sterilization |

|---|---|

| Beam Current | Primary factor affecting surface dose |

| Conveyor Speed | Crucial for dose delivery |

| Beam Width | Essential for uniformity in dosing |

Troubleshooting Dose Issues

Inconsistent electron beam sterilization doses can affect quality and safety. Operators should identify the root cause and apply targeted solutions. Common issues and recommended steps include:

| Issue | Recommended Steps |

|---|---|

| Reduced Beam Intensity | Adjust lens apertures, clean components, replace worn parts. |

| Overheating | Avoid maximum power for long periods, clean filament housing, schedule service evaluations. |

| Contamination | Follow strict cleaning procedures, use anti-contamination devices, monitor contamination rates. |

| Irregular Focus | Adjust focus settings, inspect lenses, experiment with spot sizes. |

| Vacuum Conditions | Maintain vacuum pump, control contamination, replace electron source regularly. |

Frequent causes of dose variation include maintenance issues, filament loss, alignment problems, and changes in beam parameters. Regular maintenance and monitoring help maintain consistent electron beam sterilization results. Operators should document all adjustments and monitor outcomes to ensure ongoing quality and safety.

Conclusion

Scan width and conveyor speed directly determine the electron beam dose delivered to products. Operators achieve optimal results by balancing these parameters and monitoring dose consistency. Regular audits, validation runs, and real-time monitoring systems help maintain accuracy. Automated controls and routine maintenance further support reliable operation.

Checklist for Effective Dose Control:

- Confirm accurate dose distribution and perform validation runs.

- Conduct regular dose audits and mapping.

- Assess product placement and density.

- Maintain equipment and calibrate controls.

- Use sealed packaging and document sterilization details.

Tip: Monthly quality assurance and ongoing operator training improve process reliability and safety.

FAQ

How Does Scan Width Affect Electron Beam Dose?

Scan width determines the area exposed to the electron beam. A wider scan width can reduce dose concentration. Operators must match scan width to product size for uniform coverage. Overscan may cause dose loss.

Tip: Adjust scan width to minimize wasted energy.

Why Should Operators Regularly Check Conveyor Speed?

Conveyor speed controls exposure time. Faster speeds lower the dose, while slower speeds increase it. Regular checks help maintain consistent product quality and safety.

- Operators should verify speed settings before each production run.

What Happens If the Dose Is Too High or Too Low?

A dose that is too high can damage products or change their properties. A dose that is too low may not sterilize effectively.

| Dose Issue | Possible Effect |

|---|---|

| Too High | Product damage |

| Too Low | Incomplete sterilization |

Can Operators Adjust Both Parameters During a Production Run?

Yes, operators can adjust scan width and conveyor speed during production. Real-time monitoring helps maintain the correct dose.

Note: Document all changes for process traceability.

What Tools Help Verify the Delivered Dose?

Operators use calibrated dosimeters to measure the absorbed dose. These tools provide accurate feedback on process performance.

- Regular calibration ensures reliable results.