Electron beam sterilization does not significantly raise the temperature of medical devices or food. Scientists describe this process as a ‘cold process‘ because it uses ionizing radiation, not heat, to achieve sterilization. Most products experience only a small temperature increase, with high-water-content items rising by just 2-5°C at standard doses. Users rely on this method for temperature-sensitive products, including food and medical devices. Up to 60% of medical devices worldwide can be sterilized with this technology, making it a trusted choice for industries that demand safety and precision.

Key Takeaways

- Electron beam sterilization is a ‘cold process’ that minimally raises temperatures, making it safe for heat-sensitive products.

- This method effectively sterilizes up to 60% of medical devices worldwide, ensuring safety and precision in healthcare.

- E-beam technology offers a fast and reliable way to eliminate pathogens without damaging the quality of food or medical devices.

- The process generates minimal heat, typically only 2-5°C, preserving the integrity of sensitive materials and products.

- Facilities should consult experts for proper dose mapping and validation to ensure effective sterilization of delicate items.

Electron Beam Sterilization Process

E-Beam Technology Overview

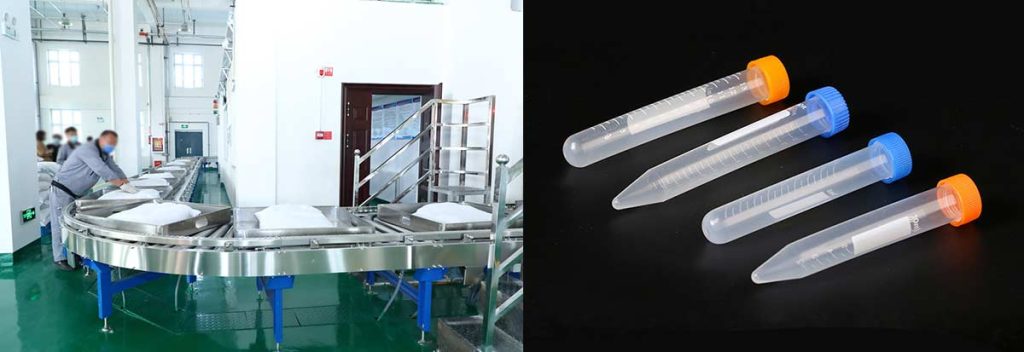

E-beam technology uses advanced electron beam irradiation equipment to sterilize products quickly and efficiently. Facilities rely on high-speed accelerators that generate a concentrated stream of electrons. These electrons pass through products, breaking down the DNA of bacteria and other harmful microorganisms. The process operates continuously, allowing for rapid treatment of large batches.

The main steps in the sterilization process include:

- Staff receive and check in the product.

- Operators load boxes in a single layer onto a conveyor.

- The product moves through a curtain of electrons, where e-beam technology sterilizes it.

- The product is released according to ISO 11137/13485 and FDA guidelines.

- The product is returned to the customer promptly.

A key advantage of e-beam technology lies in its ability to adjust energy levels. Higher energy levels allow deeper penetration, which is essential for sterilizing dense medical devices or food items. Facilities select the appropriate energy based on the product’s density and packaging.

| Key Component | Description |

|---|---|

| Electron Beam Generation | A concentrated, highly charged stream of electrons generated by accelerators. |

| High-Speed Accelerators | Sterilizes low-density, uniformly packaged products quickly and effectively. |

| Dosimetric Dosing | Eliminates post-sterilization testing and expedites distribution logistics. |

| Material Modification | Can modify polymers and enhance material properties. |

| Controlled Radiation | Uses tightly controlled radiation to eliminate pathogens and ensure product safety. |

| Reliable Technology | Modern E-Beam systems are designed for > 95% uptime and supported by trained technicians. |

| Sustainable Process | Utilizes clean electricity and produces no lingering radiation or dangerous residues. |

Non-Thermal Method

E-beam technology stands out as a non-thermal process. Unlike traditional sterilization methods that use heat, e-beam technology does not rely on elevated temperatures. This feature makes it ideal for temperature-sensitive products, such as certain medical devices and foods.

- Electron beam sterilization is a non-thermal process, so it causes minimal temperature changes.

- Other methods, like steam or dry heat, can damage sensitive materials.

- E-beam technology offers shorter exposure times, reducing the risk of product degradation.

Scientific studies confirm that e-beam technology inactivates bacteria without raising product temperatures significantly. Researchers classify it as a non-thermal process because it does not use heat to sterilize. Facilities can safely use e-beam technology for products that cannot withstand high temperatures, ensuring both effectiveness and product integrity.

Tip: E-beam technology provides a fast, reliable, and non-thermal process for sterilizing products, making it a preferred choice for industries that require gentle handling of sensitive items.

Temperature Effects

Minimal Heat Generation

Electron beam sterilization stands out for its minimal heat generation. The process uses irradiation to target and destroy pathogen DNA, but it does not rely on high temperatures. Facilities use low energy levels, which means the temperature rise during treatment remains very small. This feature protects sensitive products and maintains their quality.

Several factors contribute to the low temperature rise seen in electron beam sterilization:

| Factor | Explanation |

|---|---|

| Low Energy Levels | The process uses low energy levels that do not significantly increase the temperature of the products being sterilized. |

| Avoidance of Radioactivity | The irradiation process is designed to avoid generating radioactivity and chemical residues, enhancing safety and efficiency. |

| Compatibility with Heat-Sensitive Materials | E-beam sterilization operates at low temperatures, making it suitable for materials that would degrade under higher temperatures. |

Operators can safely sterilize medical devices, food, and other sensitive items without risking damage from heat. The process does not create lingering heat or chemical residues. This approach supports public health by ensuring that products remain safe and effective after treatment.

Note: Minimal heat generation means that even products with strict temperature limits can undergo irradiation without concern for thermal damage.

Data on Temperature Rise

Researchers have measured the temperature rise in many product categories during electron beam sterilization. Most products experience only a small increase in temperature, usually between 2°C and 5°C. This small change does not affect the structure or function of most items.

The following table summarizes published data on temperature rise and product effects:

| Product Category | Key Findings |

|---|---|

| Medical Devices (PMMA) | Detailed assessment after irradiation at 25 and 50 kGy. Minimal effects at 25 kGy. At 50 kGy, a 10% reduction in flexural strength and 2% in transparency. |

| Space Foods | E-beam processing is a non-thermal technology, resulting in minimal changes to nutritional or sensory attributes. |

| Medical Devices (PMMA) | E-beam sterilization at 25 kGy shows no alteration in mechanical and optical properties, while 50 kGy reduces flexural strength and transparency. |

These findings show that temperature rise remains minimal, even for sensitive products. Medical device sterilization at standard doses does not change the mechanical or optical properties of most devices. Food products also retain their nutritional value and taste, supporting public health goals.

The small temperature rise during irradiation ensures that microbial reduction occurs without damaging the product. Pathogen inactivation happens quickly, and the process does not compromise product safety. Public health agencies recognize electron beam sterilization as a reliable method for controlling pathogen risks in both medical and food sectors.

Tip: Facilities can use electron beam sterilization for products that cannot tolerate large temperature changes. This method supports both product quality and public health by minimizing the risk of heat-related damage.

Product Safety

Medical Device Sterilization

Medical device sterilization with e-beam radiation ensures that products meet strict safety standards. Regulatory agencies require every device labeled as sterile to have a validated sterilization process. They evaluate the materials used, the stability of the product under irradiation, and the selection of the sterilization dose. Agencies also require dose mapping, process certification, and regular audits to maintain documentation and demonstrate process viability. The choice of sterilization method directly affects the device’s materials and function.

E-beam sterilization uses ionizing radiation to deactivate microorganisms. Most medical devices, such as syringes, catheters, and wound care products, tolerate e-beam radiation well. However, some materials, like polytetrafluoroethylene (PTFE), show yield stress reductions between 35% and 90% depending on the dose and packaging atmosphere. Using an oxygen-free environment during packaging can help PTFE maintain yield stress up to 46 kGy, with only a 10% reduction at 60 kGy. Careful dose selection and packaging adjustments protect sensitive devices.

Food Safety Applications

E-beam radiation plays a vital role in food safety applications. This technology extends shelf-life and reduces bioburden in food products. It ensures at least a five-log reduction of pathogens, including Salmonella, E. coli, and Listeria monocytogenes. E-beam sterilization provides a critical kill step, enhancing food safety while maintaining nutritional integrity.

Research from the National Center for Electron Beam Research at Texas A&M University supports the effectiveness of e-beam radiation in eliminating bacteria and pathogens throughout the food production process. This approach builds consumer trust and supports public health. E-beam radiation minimizes nutrient loss and preserves the sensory qualities of food, making it a preferred choice for food safety applications.

Sensitive Items

Some temperature-sensitive goods and delicate items require special consideration during e-beam radiation. These include pharmaceuticals, biologics, packaging materials, baby products, cosmetics packaging, and laboratory consumables. Accurate dose distribution is essential for consistent sterilization results. Validation runs, dose mapping, and audits confirm that the applied dose remains within safe limits. Facilities assess internal product configuration and bulk density to optimize electron penetration and ensure uniform exposure.

Operators transfer sterilized products to controlled environments to avoid recontamination. Sealed packaging and clear labeling maintain sterility during storage and transport. For sensitive items, performance qualification on multiple containers accounts for variations in dose distribution. These protocols ensure that e-beam radiation delivers safe and effective sterilization for a wide range of products.

Conclusion

Electron beam sterilization keeps medical devices and food safe by limiting temperature rise. This method works well for temperature-sensitive products, including plastics and delicate foods.

- E-beam technology supports product quality and safety, even for sensitive materials.

- It produces less waste and fewer emissions than traditional methods.

| Step | Action |

|---|---|

| 1 | Assess bioburden and material compatibility |

| 2 | Map and verify dose distribution with experts |

Facilities should consult specialists for sensitive items to ensure the best results.

FAQ

What Is Electron Beam Irradiation?

Electron beam irradiation uses a high-power electron beam to sterilize products. The process targets bacteria and viruses without raising temperatures. Facilities use this technology for shelf-life extension and decontamination of packaging in real-world applications.

Does Electron Beam Sterilization Affect Shelf-Life Extension of Meat?

Shelf-life extension of meat improves with electron beam irradiation. The process reduces spoilage organisms and pathogens. Meat stays fresh longer, supporting food safety and quality. Shelf-life extension benefits both producers and consumers.

Can Electron Beam Irradiation Be Used for Decontamination of Packaging?

Facilities use electron beam irradiation for decontamination of packaging. The process removes bacteria and viruses from surfaces. Shelf-life extension results from cleaner packaging, which protects products during storage and transport.

How Does Electron Beam Irradiation Support Real-World Applications?

Electron beam irradiation supports real-world applications in food safety and medical device sterilization. Shelf-life extension and decontamination of packaging help maintain product quality. High-power electron beam technology ensures effective results.

Is Shelf-Life Extension Safe for Sensitive Foods Like Meat?

Shelf-life extension is safe for sensitive foods like meat. Electron beam irradiation does not damage nutritional value or taste. Meat retains its quality, and shelf-life extension helps reduce waste.