Electron beam graft polymerization changes the surface of plastic materials by attaching new monomers, which gives plastics new properties almost instantly. This process can improve wear resistance and make surfaces more hydrophilic. Medical devices benefit from these changes because the materials can resist bacteria and last longer. E-beam sterilization also plays a key role in this field:

- It sterilizes a wide range of materials quickly, often within seconds.

- The process is environmentally friendly and does not use radioactive materials.

- Adoption in medical device manufacturing continues to grow due to its efficiency and sustainability.

Key Takeaways

- Electron beam graft polymerization quickly enhances plastic surfaces by adding new properties, making them more durable and hydrophilic.

- This process is environmentally friendly and does not use radioactive materials, making it a sustainable choice for medical device manufacturing.

- E-beam treatment significantly improves the bonding of coatings and adhesives to plastics, increasing their usability in various industries.

- Medical devices benefit from e-beam technology by gaining antimicrobial properties, which help reduce infections and improve patient safety.

- Careful selection of monomers and processing conditions is crucial to achieving the desired surface properties and avoiding unwanted changes in the material.

E-Beam Graft Polymerization

Principles of E-Beam on Polymers

E-beam graft polymerization uses high-energy electrons to change the surface of polymers. When the e-beam strikes a polymer, it creates reactive sites called radicals. These radicals start a chain reaction that allows new monomers to attach to the surface. This process does not damage the bulk properties of the material, so the polymer keeps its strength and flexibility.

Scientists often use advanced techniques like RAFT polymerization to control the length and structure of the grafted chains. This control helps them design polymers with specific features. For example, when they graft acrylic acid onto poly(vinylidene difluoride), the surface gains new characteristics. The choice of solvent, such as acetic acid, can also affect how well the grafting works.

Note: E-beam grafting works through a radical mechanism. This method lets researchers add new functions to the surface without changing the core of the polymer.

Surface Modification

E-beam treatment changes both the physical and chemical properties of polymer surfaces. After e-beam exposure, the surface energy increases, which improves how the material interacts with liquids. Researchers have measured these changes:

- Surface wettability with water improves by about two times.

- Wettability with glycerol increases by a factor of 1.25.

- Surface energy rises by a factor of 1.4.

These changes make the polymer more suitable for applications that need better bonding or wetting. E-beam modification also introduces new chemical groups to the surface. For instance, studies on polystyrene show that e-beam treatment adds oxygen- and nitrogen-based groups. This alters the surface chemistry and can make the material more hydrophilic or reactive.

A study on polycarbonate films found that e-beam irradiation adds carboxylic acid (COOH) groups while keeping the original ester (COO) groups. This process increases the oxidation level of the surface, which can help with further chemical reactions or improve compatibility with other materials.

| Property | Before E-Beam | After E-Beam |

|---|---|---|

| Water Wettability | 1x | 2x |

| Glycerol Wettability | 1x | 1.25x |

| Surface Energy | 1x | 1.4x |

E-beam graft polymerization gives polymers new surface properties. These changes support a wide range of uses, from medical devices to industrial coatings. The process allows for precise control, making it a valuable tool in modern material science.

Process Steps

Preparation and Monomers

Scientists begin electron-beam processing by preparing polymer substrates. They clean and dry the surfaces to remove contaminants. Next, they select monomers based on the desired surface functionality. The choice of monomer determines the new properties added to the polymer substrates. For example, acrylic acid and styrene work well for modifying PTFE, while methyl methacrylate helps generate PMMA on PTFE micropowder. Some applications use fluorinated surfactants to improve monomer distribution.

The main steps for preparing polymer substrates and monomers include:

- Cleaning and drying the polymer substrates.

- Choosing the right monomer for the target functionality.

- Deciding on the irradiation method: simultaneous irradiation (monomer applied before irradiation) or pre-irradiation (polymer substrates irradiated before monomer exposure).

- Adjusting factors such as electron beam voltage, dose, solvent, monomer concentration, temperature, and dwell time.

| Monomer | Application |

|---|---|

| Acrylic Acid | Grafting onto PTFE |

| Styrene | Grafting onto PTFE |

| N-isopropylacrylamide | Grafting onto PTFE |

| 4-Styrenesulfonate | Grafting onto PTFE |

| Methyl Methacrylate (MMA) | Grafting to generate PMMA on PTFE micropowder |

E-Beam Irradiation

During this step, electron beam processing uses specialized irradiation equipment to deliver high-energy electrons to the polymer substrates. The equipment controls the dose, energy, and duration of irradiation. These parameters directly affect the efficiency of grafting and the final properties of the material. For example, adjusting the radiation dose changes how much monomer attaches to the surface. The ratio of different chemicals, such as NR/St, also influences the mechanical properties and chemistry of the final product.

| Parameter | Optimal Value | Effect on Grafting Efficiency |

|---|---|---|

| Radiation Dose (kGy) | Varies | Directly influences monomer conversion and grafting efficiency |

| n-BA Content (phr) | Varies | Affects the grafting yield and crosslink density |

| NR/St Ratio | 80:20 | Optimal ratio for achieving better mechanical properties and grafting efficiency |

Post-Treatment

After electron beam processing, scientists wash the polymer substrates to remove unreacted monomers and byproducts. They then use analytical techniques to confirm successful grafting and study the new surface chemistry. Common methods include atomic force microscopy for surface structure, scanning electron microscopy for morphology, and energy dispersive X-ray spectroscopy for chemical composition. Fourier transform infrared spectroscopy and X-ray photoelectron spectroscopy help verify the formation of new chemical groups and analyze surface chemistry.

| Analytical Technique | Description |

|---|---|

| Atomic Force Microscopy (AFM) | Analyzes changes in the morphology of the surface and cross-section of grafted films. |

| Scanning Electron Microscopy (SEM) | Observes surface morphology after embedding and sputtering. |

| Energy Dispersive X-ray Spectroscopy (EDS) | Measures chemical composition along the cross-section to confirm graft uniformity. |

| Fourier Transform Infrared Spectroscopy (FTIR) | Verifies successful formation of grafted material through spectral analysis. |

| X-ray Photoelectron Spectroscopy (XPS) | Analyzes surface chemistry and composition. |

Note: Careful post-treatment ensures the new chemistry remains stable and the polymer substrates gain the intended properties.

New Functionalities

Hydrophilicity

Electron beam graft polymerization can make plastic surfaces much more hydrophilic. Scientists measure hydrophilicity by looking at the contact angle of water on the surface. A lower contact angle means the surface attracts water better. When they graft hydrophilic monomers onto plastics, the contact angle drops sharply. The following table shows how different concentrations of VIM (a hydrophilic monomer) affect the contact angle:

| Grafting Condition | Contact Angle Reduction (%) |

|---|---|

| VIM Concentration 50-60% (v/v) | Up to 88% |

| VIM Concentration 70% (v/v) | Not Detected (ND) |

This large reduction means the surface becomes much more water-friendly. Hydrophilic surfaces help in many applications, such as medical devices and filtration membranes, because they resist fouling and allow fluids to spread evenly.

N-vinylpyrrolidone (NVP) is highlighted as a specific hydrophilic monomer effective for grafting onto plastics, particularly low-density polyethylene (LDPE), using electron beam technologies. The study emphasizes the solventless grafting process, which is more economical and environmentally friendly compared to traditional methods.

By choosing the right monomer, researchers can control how much water the surface attracts. This control helps create plastics that work better in wet environments or need to interact with biological fluids.

Antimicrobial Properties

Plastics used in hospitals and clinics must resist bacteria. Electron beam graft polymerization allows scientists to attach antimicrobial agents directly to the surface. These agents stop bacteria from sticking and growing. Researchers have seen impressive results:

- A ~20-fold reduction in adherent bacteria counts was observed on surfaces modified with vancomycin-bearing polymer brushes compared to untreated controls.

This improvement means medical devices stay cleaner and safer for longer periods. The process does not require extra coatings or chemical treatments. Instead, the antimicrobial function becomes part of the plastic itself. Hospitals and clinics benefit from fewer infections and easier cleaning routines.

Adhesion

Many plastics, such as polyolefins, have low surface energy. This property makes it hard for paints, adhesives, or coatings to stick. Electron beam graft polymerization changes the surface chemistry and increases surface tension. As a result, coatings and adhesives bond much better. Key improvements include:

- The process modifies the surface of polyolefins, increasing surface tension and wetting properties.

- Silane coupling agents are used in conjunction with electron beam radiation to create strong interpenetrating networks.

- The electron beam initiates polymerization and grafting, leading to improved bonding of coatings.

These changes help manufacturers produce plastics that accept paints, glues, or protective layers without extra steps. Industries such as automotive, electronics, and packaging use this technology to make products more durable and reliable.

Applications in Medical Devices

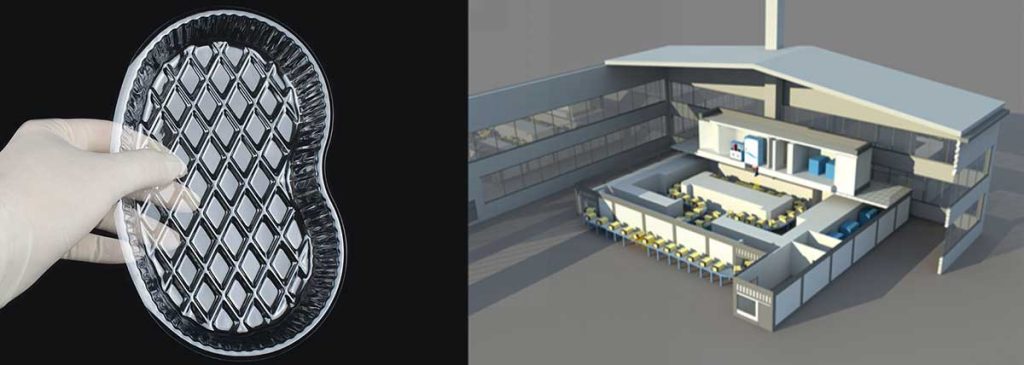

Implants

Researchers use electron beam graft polymerization to improve the surfaces of medical implants. They select polymers such as polyethylene and polyetheretherketone for orthopedic and dental devices. The process adds new chemical groups to the surface, which increases biocompatibility and reduces the risk of infection. Surgeons prefer implants with hydrophilic surfaces because these surfaces promote better integration with tissue. Medical professionals report fewer complications when using devices treated with electron beam technology. The enhanced wear resistance also extends the lifespan of implants.

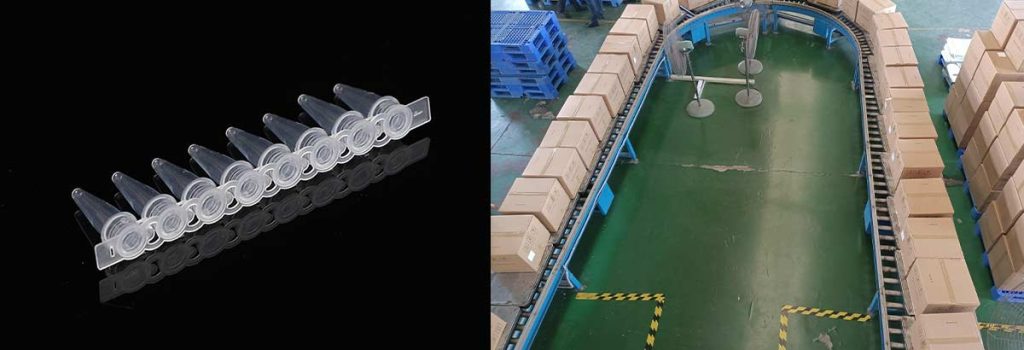

Packaging

Medical packaging must protect devices from contamination and maintain sterility. Manufacturers use electron beam graft polymerization to create packaging materials with antimicrobial and barrier properties. The process allows for the direct bonding of functional monomers, which improves the safety of packaged medical devices.

The primary mechanism of sterilization in EBS involves direct molecular damage. The high-energy electrons collide with the DNA and other vital molecules of any microorganisms present in the product, breaking the molecular bonds and rendering the microorganisms unable to reproduce or function, effectively killing them.

There is also an indirect effect where the electron beam may cause the formation of reactive molecules, such as free radicals, within the product. These reactive molecules further contribute to the inactivation of microorganisms by damaging cellular components and disrupting metabolic processes.

Medical packaging produced with electron beam graft polymerization supports a sterile environment for devices. Hospitals rely on these materials to ensure patient safety and reduce infection rates.

Membranes

Membranes play a key role in medical applications such as dialysis, filtration, and wound care. Scientists modify membrane surfaces using electron beam graft polymerization to increase hydrophilicity and reduce fouling. The study highlights that electron beam graft polymerization significantly improves the filtration efficiency of membranes by altering their surface properties, including surface chemistry, hydrophilicity, and roughness. These modifications lead to enhanced separation efficiency and resistance to fouling, demonstrating the effectiveness of this method in membrane technology.

Medical devices that use these advanced membranes show better performance and reliability. The technology enables precise control over membrane properties, which supports a wide range of medical applications.

Challenges

Technical Limitations

Electron beam graft polymerization offers many benefits, but technical challenges can affect the final product. One major issue involves unwanted crosslinking or degradation of the polymer. When high-energy electrons hit the polymer, they can break the chains or cause them to link together in ways that change the material’s properties. For example, polypropylene often shows significant changes in its physical and chemical properties after irradiation. Chain scission and degradation can weaken the material or make it less useful for certain applications. Scientists sometimes add nanoparticles, such as PET, to improve stability during irradiation.

The effects of electron beam treatment also depend on the material and its environment. In the case of bovine collagen, the presence of water influences whether the process causes chain scission or cross-linking. These technical factors require careful control of processing conditions to achieve the desired results.

| Study Focus | Findings |

|---|---|

| Polypropylene | Electron beam irradiation leads to significant changes in physico-chemical properties due to chain scission and degradation. |

| Stability Improvement | Addition of PET nanoparticles aims to enhance stability under irradiation. |

| Bovine Collagen | The effects of irradiation on collagen are influenced by water presence, leading to scission or cross-linking. |

Note: Careful selection of process parameters and additives helps reduce unwanted side effects and improves the quality of grafted polymers.

Cost Factors

Implementing electron beam graft polymerization in industry involves several cost considerations. Companies must invest in specialized electron beam equipment, which can require significant capital. These systems may also need changes to existing processes to maximize their use. Ongoing expenses include operating and maintaining the equipment. Material costs can vary, especially when using photoinitiators or chemical cross-linkers.

However, electron beam technology can also help reduce some operational costs. For example, companies may spend less on maintenance for solvent-based systems after switching to electron beam processes. The table below summarizes the main cost factors:

| Cost Factor | Description |

|---|---|

| Capital Costs | Initial investment required for electron beam systems, which may necessitate process changes to optimize utilization. |

| Recurring Costs | Ongoing expenses such as operating and maintenance costs, which can accumulate over time. |

| Material Costs | Costs associated with materials, which may vary depending on the use of photoinitiators or chemical cross-linkers. |

| Operational Cost Savings | Potential reductions in other operational expenses due to the introduction of electron beam technology, such as reduced maintenance for solvent-borne systems. |

Companies must balance these costs against the benefits of improved material performance and new functionalities.

Conclusion

Electron beam graft polymerization creates advanced polymers with tailored surfaces. Medical devices gain improved wear resistance, hydrophilicity, and antimicrobial properties. E-beam technology also integrates sterilization, supporting safer healthcare products. Researchers continue to explore new applications and optimize process conditions.

Scientists observed changes in polymer scaffold porosity and mechanical integrity after e-beam sterilization. They recommend evaluating labile linkages and crosslinks for each material.

Future innovations will expand the role of e-beam in both industry and medicine.

FAQ

What Makes Electron Beam Graft Polymerization Unique for Polymer Modification?

Electron beam-induced graft copolymerization creates new functional materials by attaching monomers to the surface of a polymer. This method preserves the strength of the original materials. The process enables precise grafting and crosslinking, which supports the integration of advanced properties and integrated sterilization.

How Does Grafting Improve the Performance of Medical Materials?

Grafting introduces new chemical groups onto the polymer surface. This change increases hydrophilicity, antimicrobial properties, and adhesion. Medical materials with antimicrobial grafts resist bacteria. The eb grafting process also supports integrated sterilization, which ensures safer patient-specific device production and enhances the strength of medical implants.

What Is the Role of Crosslinking in Polymer Graft Copolymers?

Crosslinking forms bonds between polymer chains during graft copolymerization. This process increases the strength and durability of the materials. Crosslinking polyethylene, for example, results in functional materials with improved wear resistance. The integration of crosslinking and grafting creates robust graft copolymers for demanding applications.

Can Electron Beam Grafting Support Low-Temperature Sterilization?

Yes. Electron beam grafting enables low-temperature sterilization. This method protects sensitive materials from heat damage. The eb grafting process combines modification and sterilization, which ensures that functional materials retain their strength and performance after processing.

How Do Graft Copolymers Benefit Industrial and Medical Applications?

Graft copolymers offer tailored properties for both industrial and medical uses. The copolymerization process allows for the integration of hydrophilicity, antimicrobial activity, and improved adhesion. These materials support the production of advanced devices, packaging, and membranes, all while maintaining strength and safety.

Tip: Companies can use electron beam grafting to create functional materials with unique properties for specific applications.