E-beam crosslinking transforms PEX pipe by creating strong covalent bonds between polymer chains. This process forms a three-dimensional network structure that leads to several key advantages:

- Increased durability and flexibility

- Improved thermal stability

- Superior resistance to environmental stress cracking and slow crack growth

Manufacturers choose crosslinking to deliver pipes that last longer and perform better in demanding conditions.

Key Takeaways

- E-beam crosslinking enhances PEX pipe durability and flexibility, making it suitable for demanding environments.

- The process eliminates the need for chemical additives, resulting in safer pipes for drinking water.

- Proper blending and extrusion of polyethylene are crucial for achieving uniform quality before crosslinking.

- Quality control after crosslinking ensures that only pipes meeting industry standards reach the market.

- Automation and advanced control systems can help manufacturers efficiently integrate e-beam crosslinking into their production lines.

E-Beam Crosslinking in PEX

What Is E-Beam Crosslinking?

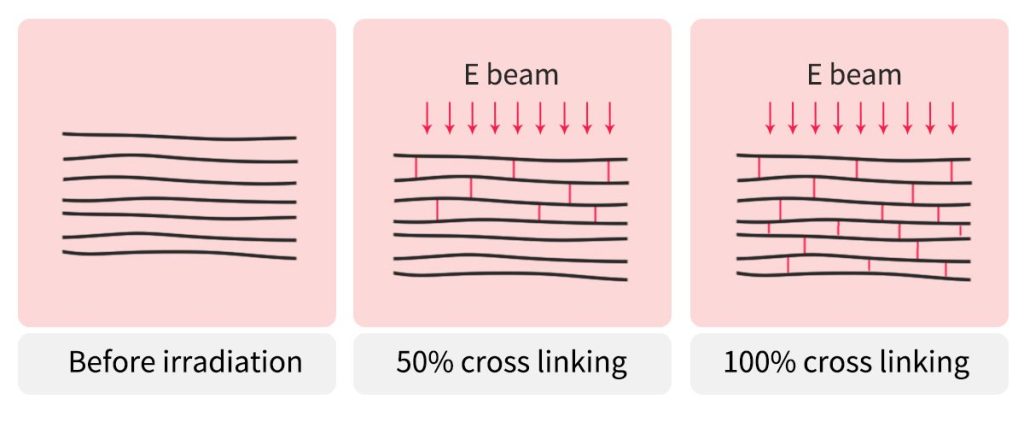

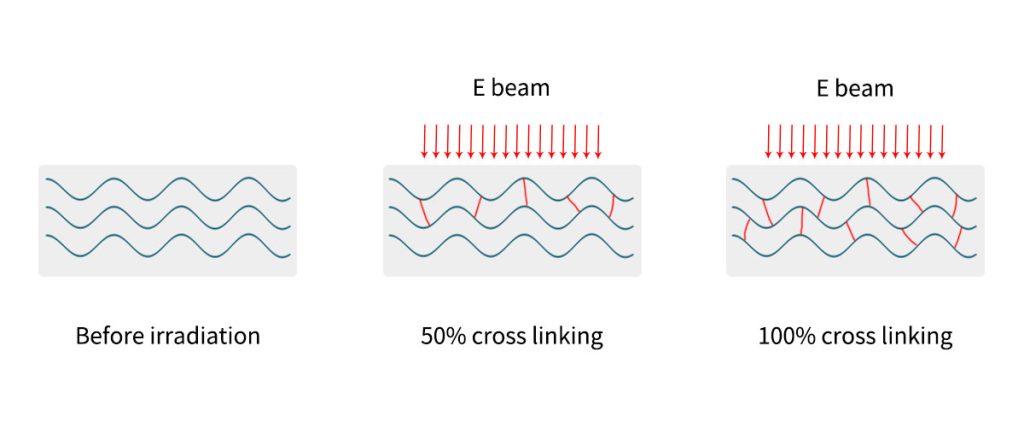

E-beam crosslinking uses high-energy radiation to alter the molecular structure of polyethylene in pipe manufacturing. This method exposes the material to a beam of electrons, which initiates chemical reactions within the polymer. The process transforms thermoplastic materials into thermosets by creating strong covalent bonds between polymer chains. These new connections restrict molecular movement and enhance the pipe’s stability against heat. As a result, the pipe gains improved tensile strength, abrasion resistance, and resistance to stress cracking.

Manufacturers often choose e-beam crosslinking for PEX because it does not require chemical additives. The process leaves no residual chemicals in the finished pipe, making it safer and more environmentally friendly. The method also operates quickly, allowing for high throughput and lower energy consumption compared to traditional chemical crosslinking techniques.

Physical Crosslinking Process

The crosslinking process begins after the pipe has been extruded and shaped. At this stage, the pipe passes through an irradiation unit where it receives a controlled dose of high-energy electrons. The electron beam crosslinking bombards the polyethylene with these electrons, generating free radicals that break existing chemical bonds. New crosslinks form, especially in the amorphous regions of the polymer, which strengthens the pipe’s structure.

During irradiation, main-chain scission can occur, and hydrogen gas may evolve as a byproduct. The process often involves multiple passes through the irradiation unit to achieve the desired level of crosslinking. This approach is similar to sterilization methods used in medical applications. The result is a pipe with enhanced durability, resistance to temperature extremes, and improved mechanical properties.

Note: The timing of e-beam crosslinking is critical. Manufacturers apply it after extrusion to ensure the pipe maintains its intended shape and dimensions while gaining the benefits of crosslinking.

PEX Crosslinking Process Steps

Pipe Extrusion and Preparation

Manufacturers begin the PEX production process by blending polyethylene with specific additives. These additives help improve the efficiency of crosslinking later in the workflow. The blended material then moves into extrusion equipment, where it is shaped into pipe. Several leading manufacturers supply extrusion lines for this purpose. For example, Maillefer offers integrated production lines that combine extrusion, forming, welding, and induction heating. Kaidemac provides high-speed PEX-b extrusion lines that use structured screws and die heads for consistent quality. Davis-Standard delivers solutions for both single-layer and multi-layer PEX pipes, while Battenfeld-Cincinnati specializes in single-screw extruders for comprehensive pipe extrusion.

The table below summarizes the typical steps involved in preparing polyethylene pipes for e-beam crosslinking:

| Step | Description |

|---|---|

| 1 | Blend polyethylene with additives to enhance crosslinking. |

| 2 | Use conventional thermoplastic processing equipment to shape the pipes. |

| 3 | Cure the shaped pipes off-line by exposing them to electron beam irradiation. |

| 4 | If necessary, run the pipes through the electron beam unit multiple times to achieve the desired crosslinking density. |

Tip: Proper blending and extrusion ensure that the pipe has uniform wall thickness and consistent quality before crosslinking begins.

Electron Beam Irradiation Equipment

After extrusion, the pipe enters the crosslinking stage. At this point, electron beam irradiation equipment becomes essential. This equipment generates a focused stream of high-energy electrons. The pipe passes through the irradiation chamber, where the electrons penetrate the pipe wall and initiate the crosslinking process. Operators can adjust the energy level and exposure time to control the degree of crosslinking. Some production lines require multiple passes through the electron beam to reach the desired crosslinking density.

Electron beam irradiation equipment offers several advantages. It allows for precise control over the crosslinking process. It also eliminates the need for chemical crosslinking agents, which can leave residues in the pipe. The equipment operates efficiently and supports high production speeds, making it suitable for large-scale manufacturing.

Crosslinking Process Execution

The crosslinking process execution starts once the pipe enters the irradiation chamber. The electron beam crosslinking exposes the pipe to a controlled dose of electrons. These electrons break some of the existing chemical bonds in the polyethylene and create new covalent bonds between polymer chains. This transformation changes the pipe from a thermoplastic to a thermoset material.

Operators monitor the process closely. They check the energy dose, exposure time, and the number of passes through the irradiation unit. These factors determine the final properties of the pipe. The goal is to achieve a uniform crosslinking density throughout the pipe wall. Consistent crosslinking ensures that the pipe will have the desired strength, flexibility, and resistance to temperature extremes.

Note: The crosslinking process occurs after the pipe has been fully formed. This timing helps maintain the pipe’s shape and dimensions.

Post-Processing and Quality Control

After crosslinking, the pipe undergoes post-processing steps. These may include cooling, cutting to length, and surface inspection. Quality control plays a critical role at this stage. Technicians test the pipe for crosslinking density, mechanical strength, and dimensional accuracy. They may use techniques such as gel content analysis or tensile testing to verify that the pipe meets industry standards.

Manufacturers also inspect the pipe for surface defects or irregularities. Any pipe that does not meet specifications is removed from the production line. Consistent quality control ensures that only pipes with optimal crosslinking and performance reach the market.

Quality control safeguards the reliability and safety of every PEX pipe produced using e-beam crosslinking.

Benefits of E-Beam Crosslinked PEX

Enhanced Durability

E-beam crosslinking creates crosslinked polymers that improve the durability of PEX pipe. The process forms a network of strong bonds, making the pipe more resistant to wear and tear. Crosslinked materials produced by this method show a balance between flexibility and strength. For example, studies show a 31% increase in flexibility with only a 20% reduction in strength. This means the pipe can bend without breaking, while still maintaining its toughness. The result is a product that lasts longer and performs well in demanding environments.

Temperature Strength

Crosslinked polyethylene stands out for its ability to handle temperature extremes. E-beam crosslinking changes the structure of the pipe, allowing it to maintain its shape and function in both hot and cold conditions. Crosslinked materials resist deformation when exposed to high temperatures, making them suitable for potable water systems. The pipe does not become brittle in cold weather, which helps prevent cracking or leaks. This temperature strength makes crosslinked polymers a reliable choice for plumbing and heating applications.

Resistance to Stress Cracking

E-beam crosslinking gives PEX pipe excellent resistance to environmental stress cracking. The process creates crosslinked materials that can withstand repeated bending and pressure changes. PEX-C pipes, made with electron beam crosslinking, offer good flexibility and memory. The physical properties of these pipes depend on the intensity and duration of the electron beam exposure. This method helps prevent cracks from forming, even when the pipe faces stress from installation or daily use.

Note: Resistance to stress cracking is a key reason why many builders and plumbers choose crosslinked polymers for long-term water supply systems.

Comparison to Other Methods

Manufacturers use different methods to create crosslinked materials, but e-beam crosslinking offers unique advantages. Unlike chemical methods, e-beam crosslinking does not leave residues in the pipe. This makes the pipe safer and more suitable for potable water. The process also allows for precise control over the degree of crosslinking, which helps maintain consistent quality. E-beam crosslinked PEX pipe combines flexibility, strength, and safety, setting it apart from other crosslinked materials used in plumbing.

Manufacturer Considerations

Cost and Scalability

Manufacturers often face high initial investment when adopting e-beam crosslinking for PEX pipe production. The installation and maintenance of accelerator systems can challenge small and medium enterprises. Skilled technicians are necessary to operate these advanced systems, but many regions lack enough qualified workers. Companies may need to invest in training programs, which adds to costs. Regulatory approval also presents a challenge. Different regions have unique standards, and multinational operators may see compliance costs rise by 15–20%. The absence of harmonized global standards can further complicate operations.

| Challenge | Description |

|---|---|

| High Initial Investment | The upfront cost of installing and maintaining systems of e-beam accelerator can be prohibitive for small and medium enterprises. |

| Skilled Workforce Requirement | Operation and maintenance of these advanced systems require specialized expertise, which may not be readily available across regions. |

| Complex Regulatory Approval Process | Compliance with various international standards can delay implementation, especially in the medical and food sectors. |

| Technological Integration Barriers | Difficulty in integrating legacy systems with new accelerator technologies may hinder adoption in established industries. |

Despite these challenges, e-beam crosslinking supports scalable production. Automation ensures consistent crosslinking density and product quality. Integrated multi-layer extrusion minimizes handling and boosts throughput. Advanced control systems help manage complex processes, making it easier to produce crosslinked polymers and crosslinked materials at scale.

Implementation Tips

Manufacturers can use several strategies to integrate e-beam crosslinking into existing production lines:

| Strategy | Benefits |

|---|---|

| Automation of cross-linking | Ensures consistent cross-linking density and final product quality. |

| Integrated multi-layer extrusion | Minimizes intermediate handling, improves layer adhesion, and boosts production throughput. |

| Advanced control systems | Manages complexities of multi-material processes to achieve desired product characteristics. |

To overcome workforce shortages, companies can form strategic partnerships or seek government support. Investment in training programs helps develop the necessary expertise. Regulatory compliance remains important. For example, a European supplier launched a new PEX-c product line that meets strict standards for biocompatibility and performance. Another major player obtained certifications for crosslinked polyethylene plumbing systems, ensuring compliance with fire safety and water hygiene codes.

Manufacturers must also consider environmental and safety factors. PEX pipe can allow chemicals and oxygen to permeate, which may lead to contamination in closed loop water systems. Harmful substances like MTBE and TBA can leach from crosslinked polymers into drinking water, raising health concerns. Companies should monitor these risks and follow best practices to ensure safe, high-quality crosslinked materials.

Conclusion

E-beam crosslinking in PEX manufacturing follows a clear process:

- The manufacturer extrudes the pipe from low-density polyethylene.

- The pipe moves into an electron beam chamber.

- The radiation breaks molecular links, creating crosslinked materials with improved properties.

These crosslinked materials offer greater durability and temperature resistance. Manufacturers gain reliable pipes that perform well in demanding environments. E-beam crosslinking stands out as a smart choice for those seeking advanced pipe performance.

FAQ

What Is the Main Advantage of E-Beam Crosslinking in PEX Pipe Manufacturing?

E-beam crosslinking creates strong, uniform bonds in the pipe. This process improves durability and temperature resistance. Manufacturers do not need chemical additives, so the finished pipe remains safe for drinking water.

How Does E-Beam Crosslinking Affect Pipe Flexibility?

E-beam crosslinking increases flexibility while maintaining strength. The pipe bends easily without breaking. This property helps during installation and reduces the risk of cracks.

Is E-Beam Crosslinked PEX Safe for Drinking Water?

Yes. E-beam crosslinking does not leave chemical residues in the pipe. The process uses only high-energy electrons. This makes the pipe suitable for potable water systems.

What Equipment Is Needed for E-Beam Crosslinking?

Manufacturers need an electron beam accelerator and an irradiation chamber. Operators use control systems to adjust energy levels and exposure time. Proper equipment ensures consistent crosslinking and product quality.

Can Small Manufacturers Use E-Beam Crosslinking?

Small manufacturers may face high initial costs for equipment and training. However, automation and partnerships can help reduce barriers. Over time, e-beam crosslinking supports scalable production and consistent quality.